Customer demand:

One large auto parts group company was established in 2011 in Shanghai. The company's business covers tailgate, bumper, spoiler, wheel eyebrow, grille, threshold, carrier, etc. It has established factories in major automobile manufacturers' gathering areas in China to provide customers with zero-distance real-time supply and service. At the same time, the company has entered the global procurement system of many multinational automobile enterprises, to provide international customers with products and services beyond expectations.

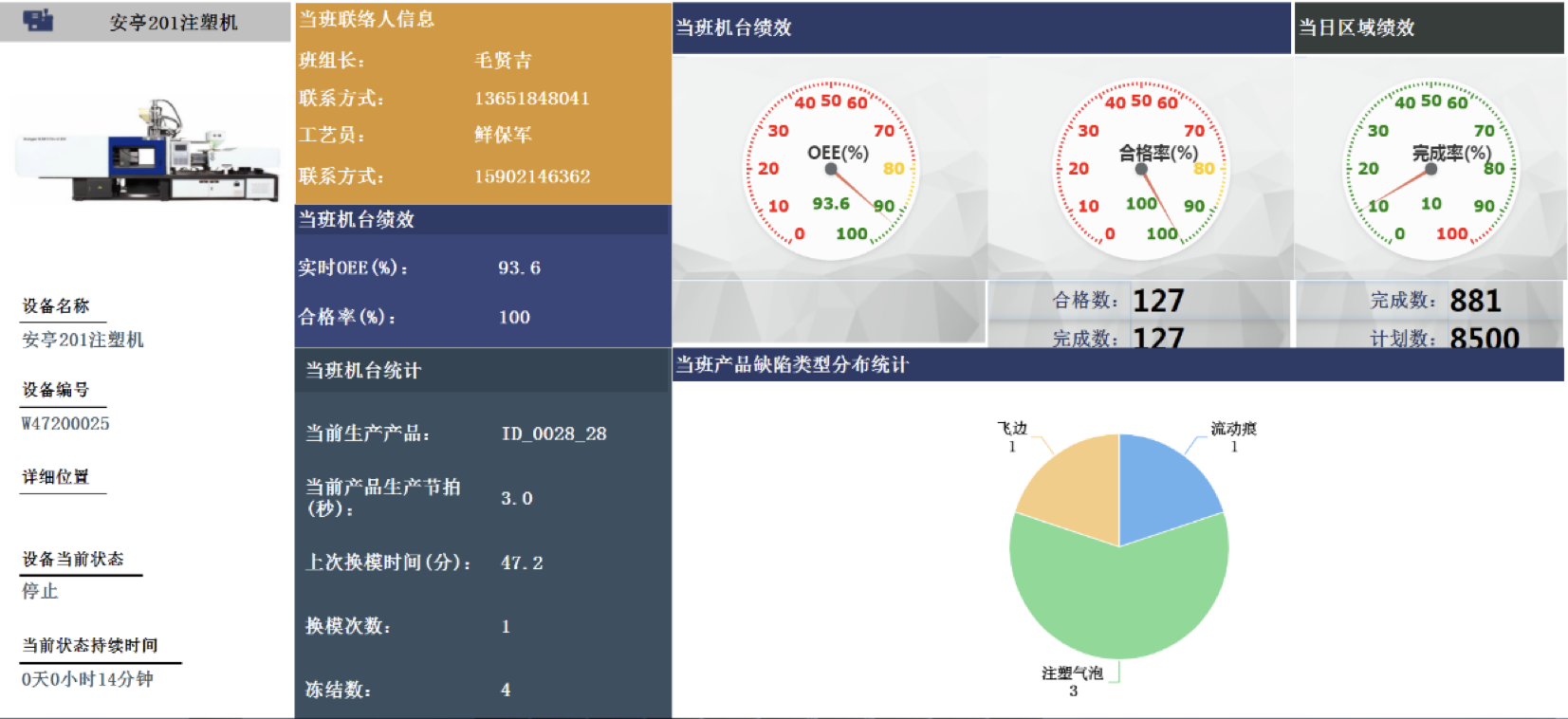

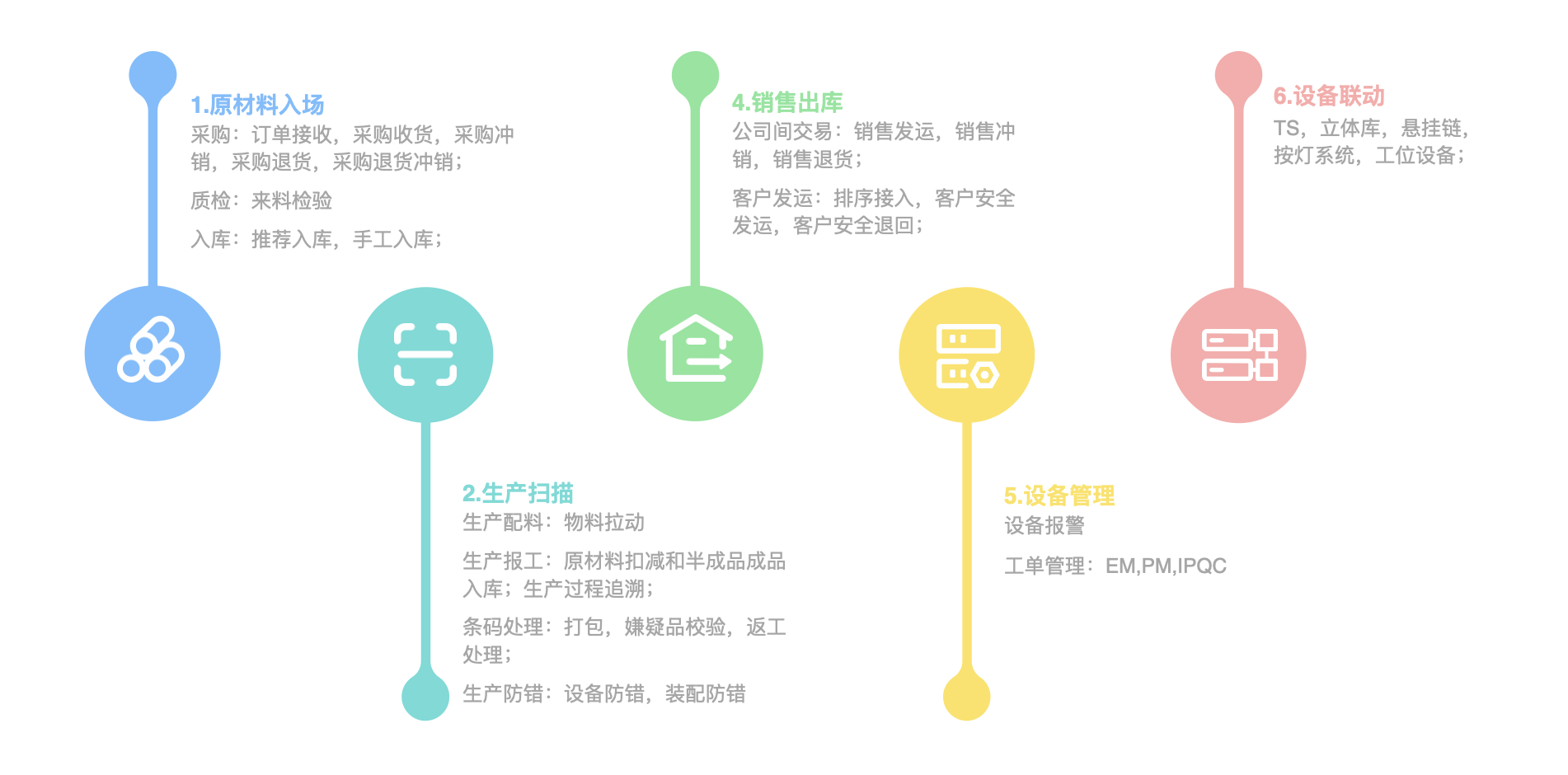

The company's own enterprise informatization construction strategic objectives and customers' requirements for informatization interconnection, quality traceability and other aspects, combined with the characteristics of numerous subsidiaries and branches, informatization level and management system and versions of branches and subsidiaries are different. The group decided to build a new information management platform, including warehouse management WMS, production management MES, MRP material demand planning, inventory management, order management, supplier management, quality management, sales management, equipment linkage, OEE and other functional modules. The system platform can be flexibly and effectively deployed in each branch company to achieve comprehensive information unified management.

Solutions:

· Customer (JIT/JIS) order pulling

Through EDI interface, to realize GM, Volkswagen, SAIC and other OEMs pull demand in real time;

By analyzing automatically to release orders, according to customer pass order information and configuration information.

· Release of work Order (Automatic release from order pool & Manual emergency release)

Automatically release work orders and accurately put them into production line according to factory capacity and actual production schedule;

Order sequence check, match whole vehicle or single assembly order;

Customer order-empty, insert single production, visual order printing;

Kitting pulling task generation.

· Unified production model definition

Solve what to do by unifying the core definition of the manufacturing model,Where do we do it? How do we do generative process control.