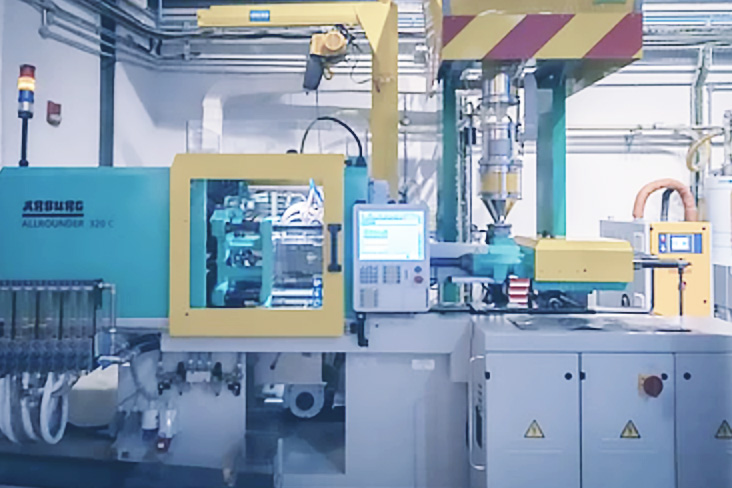

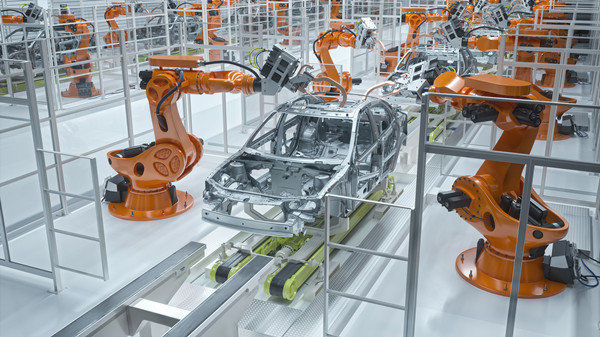

Successful case of electronic manufacturing intelligent industry

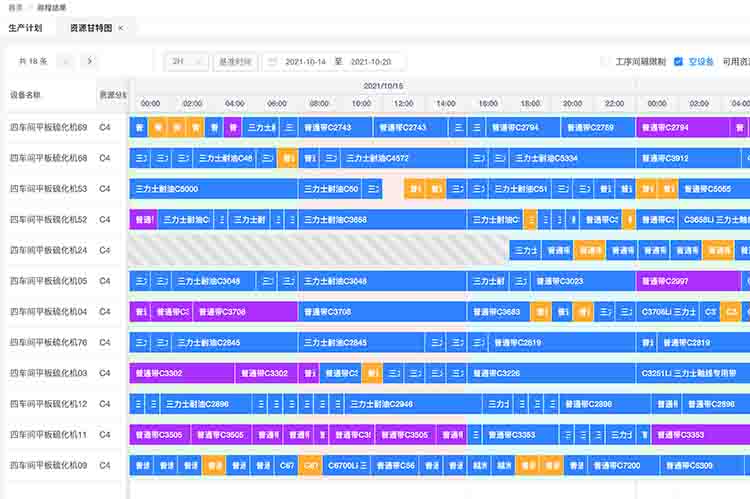

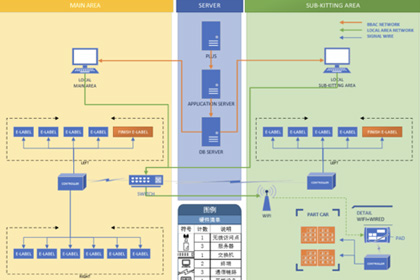

Cross-system data integration: data covers operational KPIs, quality performance, manufacturing execution, exception management, equipment management, finished product and raw material management, etc. Data were collected from ERP, MES, WMS, Andon and other systems, and presented as business demand data after big data analysis and calculation.

details→