股票代码:833352

中文|

Characteristics and demand for Assembly Manufacturing industry :

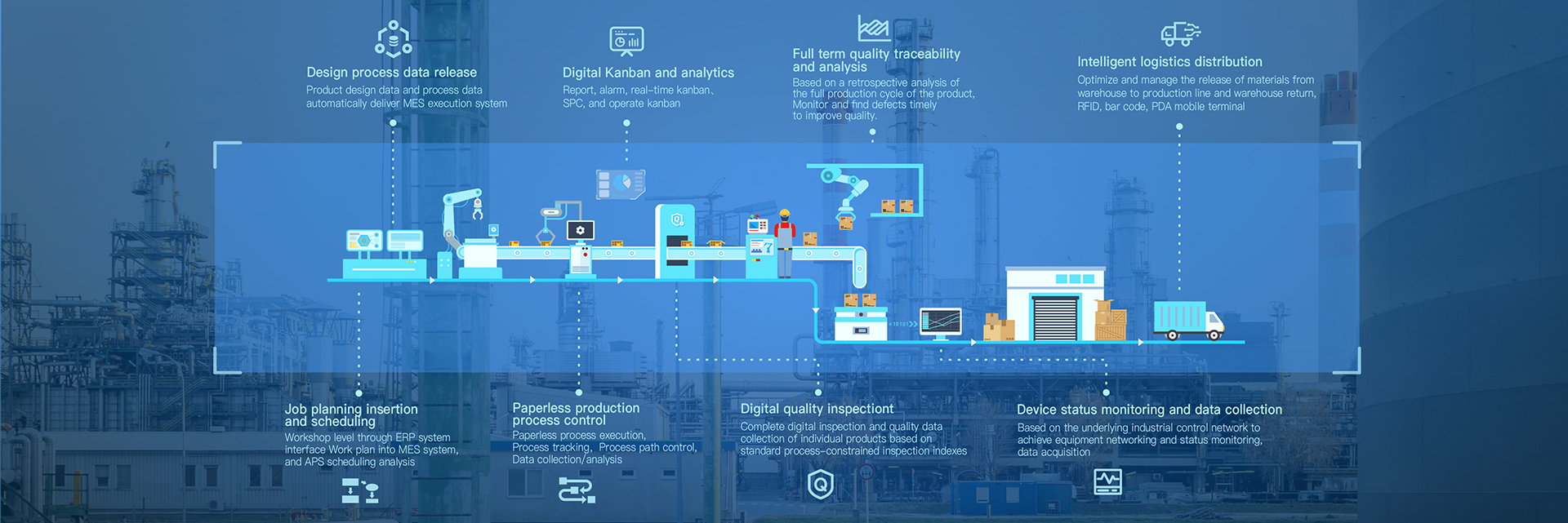

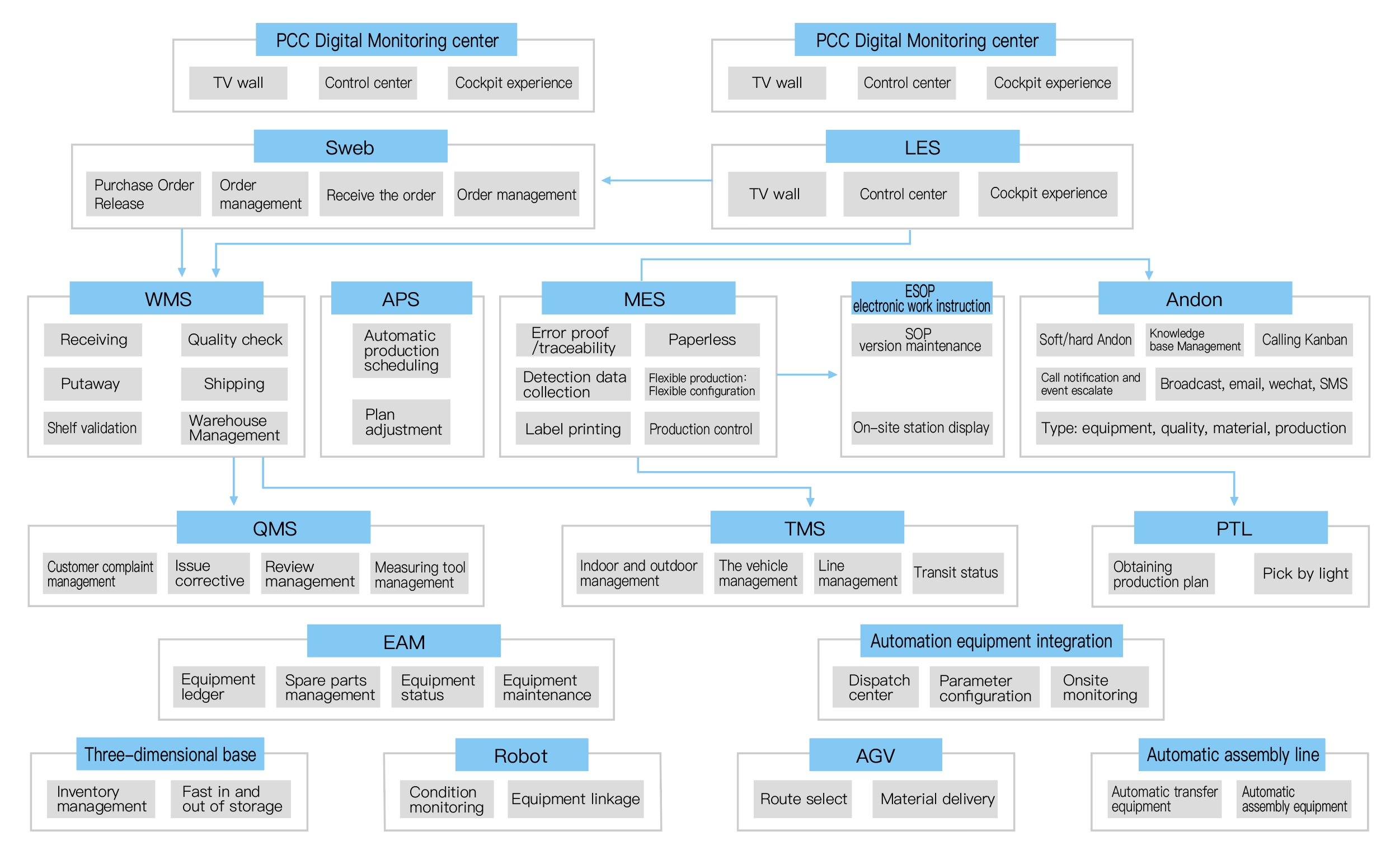

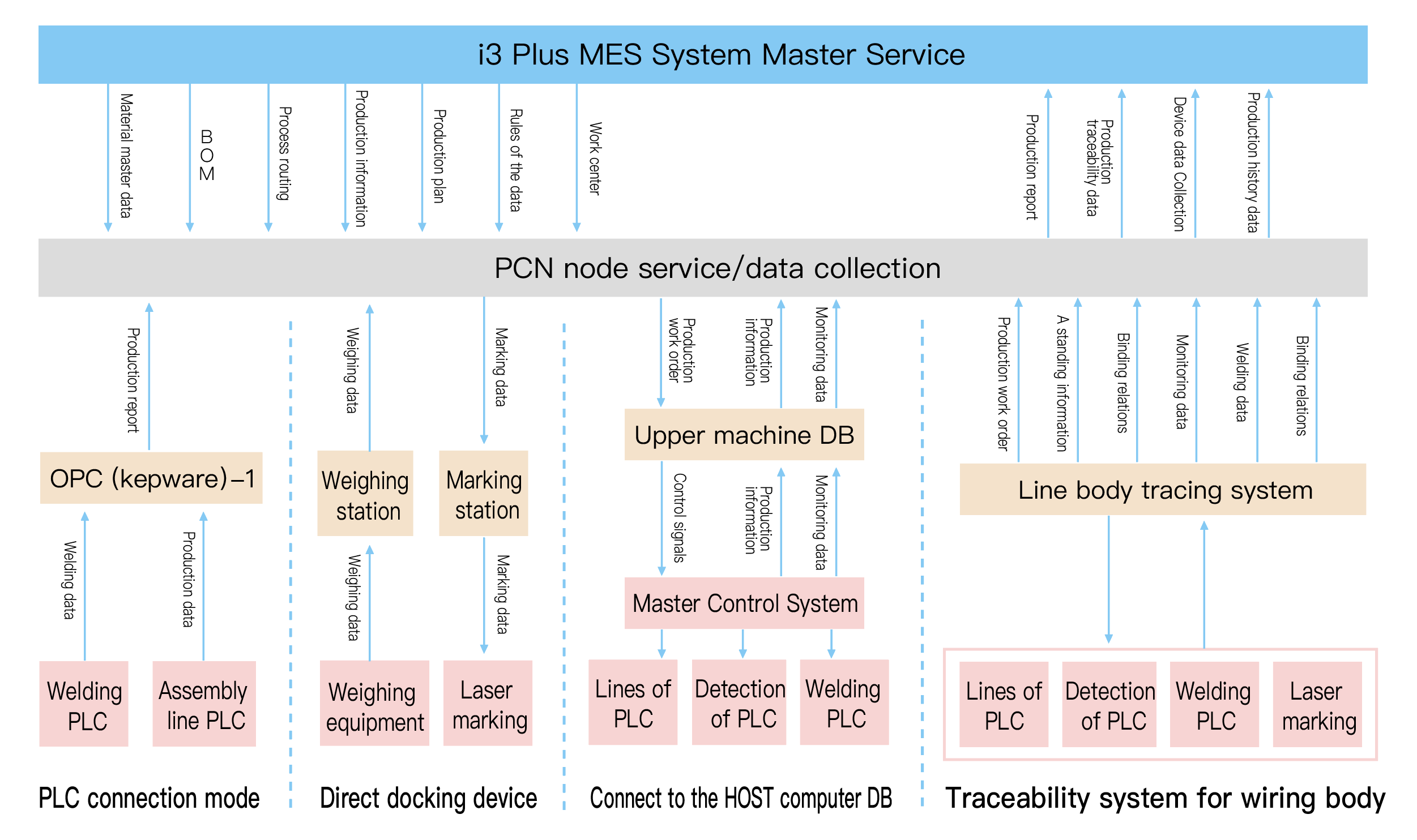

· Cross-system integration to break down information silos and digital barriers

Based on MES system as the core of intelligent manufacturing, the whole link open up the information channel;

Customer order (JIT/JIS) seamless docking, intelligent production order scheduling, manufacturing process data collection, whole process quality traceability.

· Efficient real-time equipment status monitoring and data collection

Collecting a large number of real-time production data through the MES system data acquisition function, meanwhile real-time analysising and processing of the data;

Through two-way communication with the planning level and production control level, MES system accurately collects and controls the flow program according to the technological process;

Through MES terminal of edge computer, high-speed interaction of real-time data acquisition is realized.

· Adapt to multiple products, complex process to achieve information control requirements

Intelligent process control, meet the requirements of multi-product parallel production;

Build process modeling and process configuration quickly in response to changing and complex process and manufacturing requirements.

Solution:

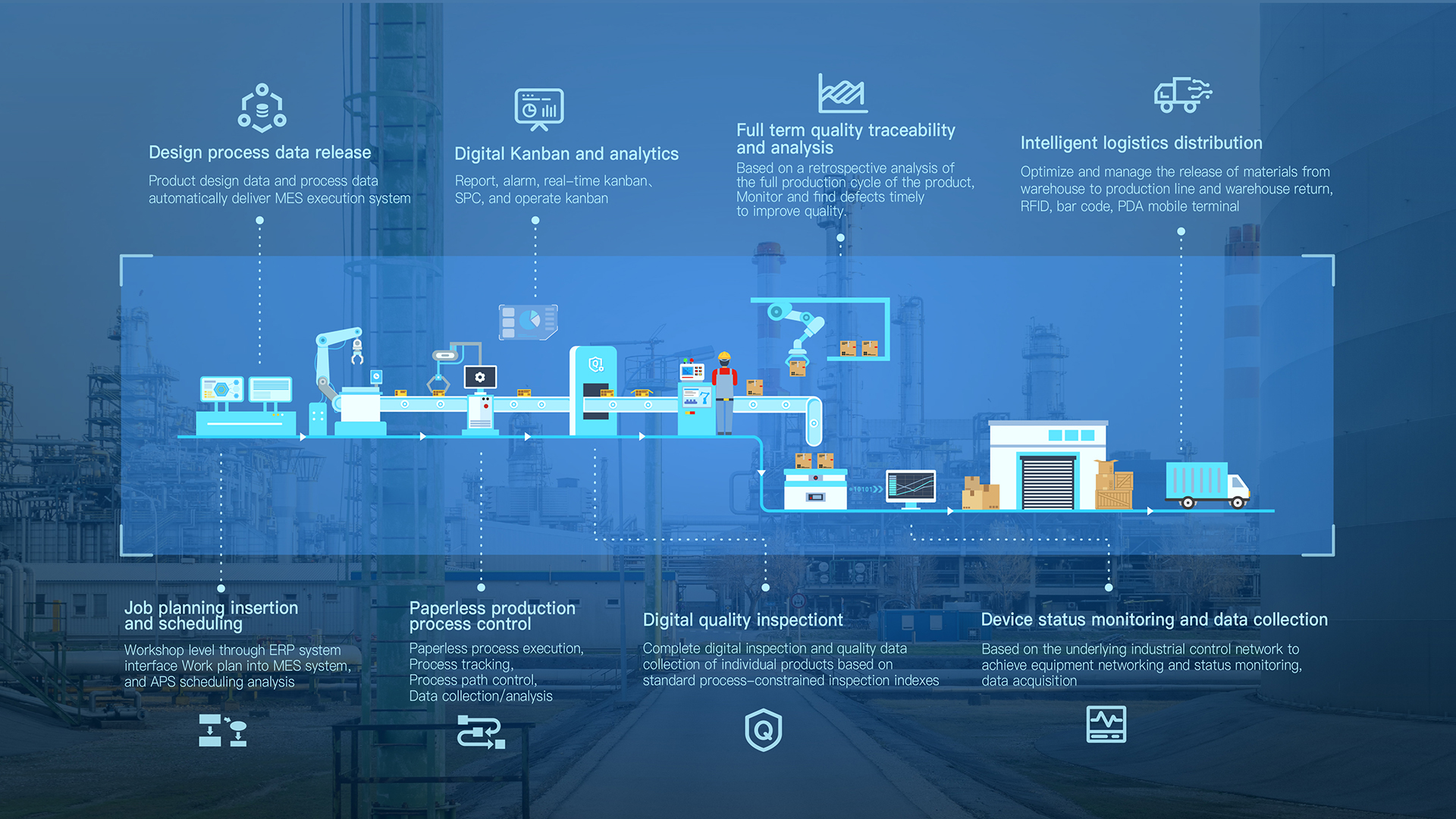

· Based on i3 Plus highly information integrated intelligent workshop platform, to build and achieve intelligent manufacturing perfectly

The overall blueprint of intelligent factory is highly integrated across systems;

Whole process equipment monitoring and implementation of data acquisition and interaction.

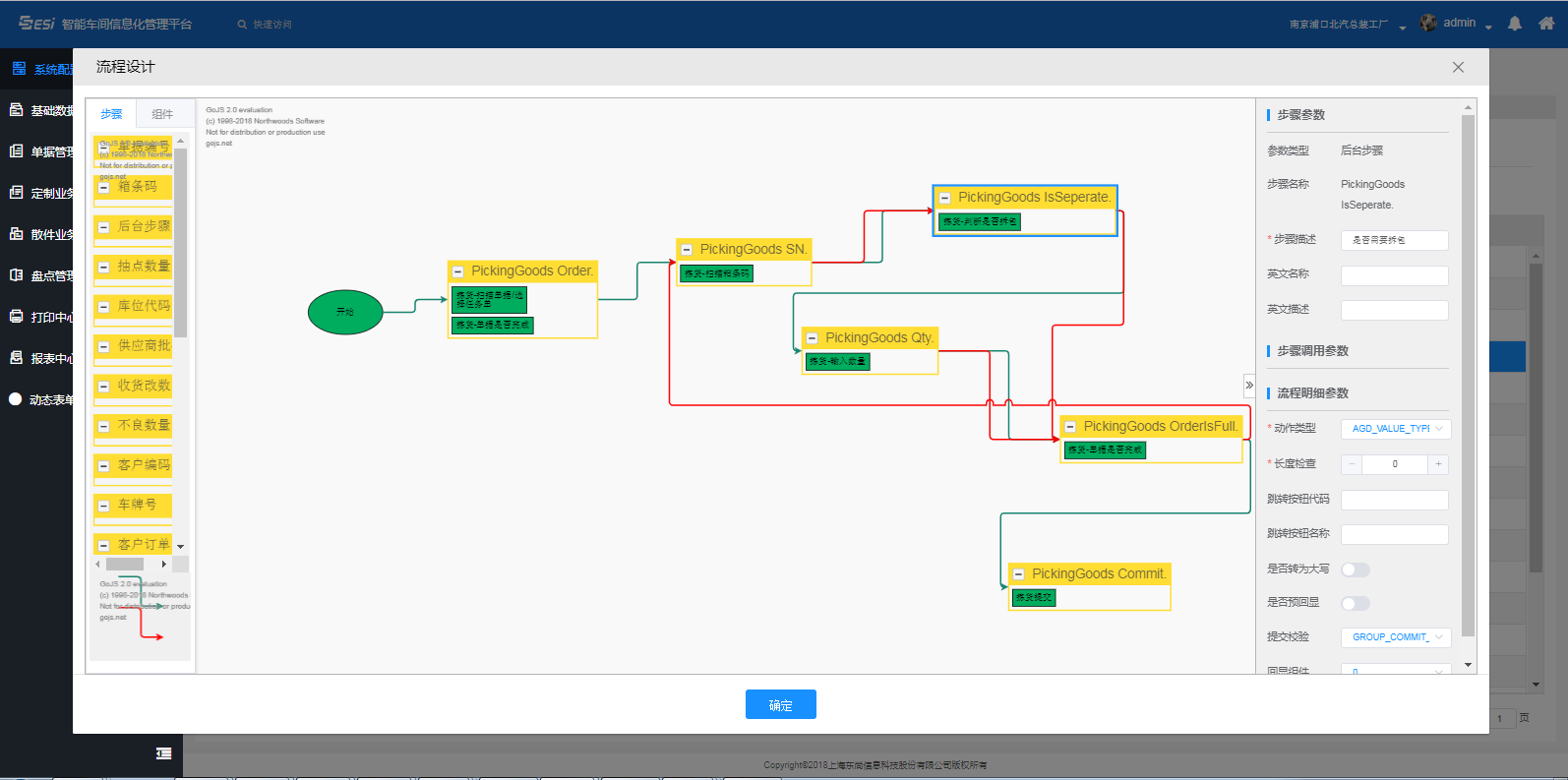

· Flexible process configuration

Fast plant modeling in accordance with customer, product and process requirements;

Compartmentalization, drag-and-drop process configuration, to realize process visualization and dynamic layout;

Support for modular hot swap and insensitive rapid application deployment at the front and back ends.

· "smart number" management at Enterprise level

Multi-dimensional monitoring of plant operation status (production, logistics, equipment, quality, safety, etc.)