股票代码:833352

中文|

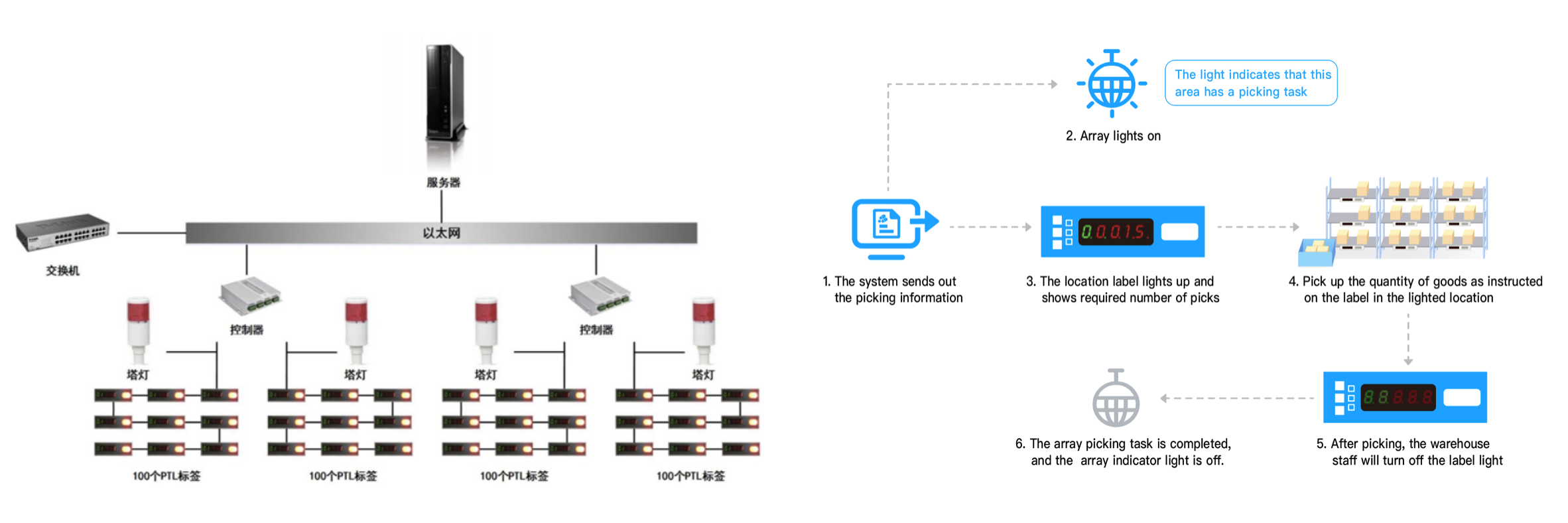

With the development of logistics technology, information automation and job automation equipment play a key role in improving the efficiency of order picking operations. Currently chosen in the center of the logistics system, the electronic label is the most commonly used auxiliary selection system, its basic idea is visual operation guide the indicator system, mainly through the control of a set of electronic device installed on the shelf, by light signal and the digital display, guide the chosen personnel right and fast for the picking work.In the system, electronic tags replace traditional paper picking forms, and the pickers only need to follow the lights. has been widely applied to logistics distribution center from all walks of life.

PTL electronic picking system purpose:

·The use of electronic label picking, can greatly speed up picking speed, improve picking accuracy, improve picking efficiency, reduce picking costs.

·Paperless operation, no need to print out of the warehouse, sorting sheet and other paper documents. Reduce the time of document processing before warehouse and paper saved.

·The use of electronic labels to pick up goods, simple and reliable operation, any personnel after a few minutes of simple training can be on duty, reduce personnel training costs.

·Picking control software can not only monitor the picking process in real time, record the picking situation, but also carry out real-time replenishing tips, assist inventory operations, and can be seamlessly connected with the logistics distribution system.

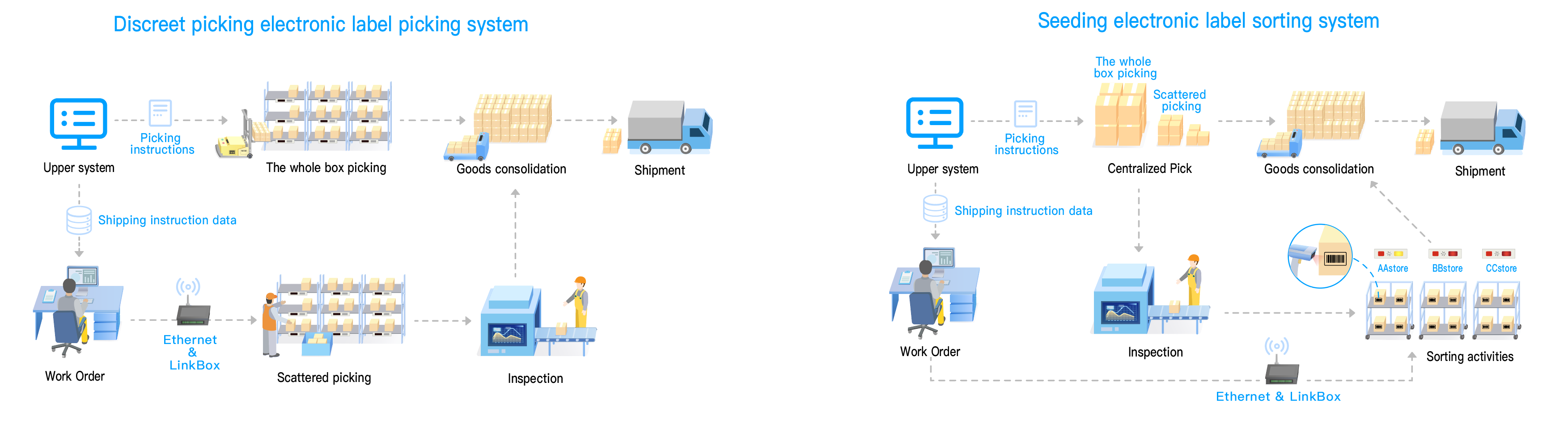

Common picking methods: DPS, DAS

Pick up (DPS) operating principle: for each order, the picker will pick out and collect the goods one by one according to the goods information on the order to the corresponding storage location manually. The advantage is that there is no follow-up operation for the order, and the skill requirement for personnel is so low, simple and direct. Disadvantage is with single order picking, leading low efficiency.

Served-in (DAS) operating principle: collect orders into one batch in a certain period of time, and sum the quantity of goods according to the type of goods, the warehouse staff will choose goods according to the goods, and then send the goods to each requisition list by way of separation. Advantages are multiple orders at the same time picking, with high efficiency; The disadvantage is that it requires high skills of personnel. After picking, the order needs to be split and picked again.

· Old-used picking:

Regardless of the method of picking, the Old-used picking process requires the printing of a picking slip - > manual search for storage space for picking. In the process of picking, it is necessary to carry out picking operation according to warehouse location and personal experience. If there are many kinds of warehouse location and materials, there will be repeated paths and too long which affect picking efficiency. In addition, if the warehouse space is large and the picking area span is wide, handling will also become difficult.

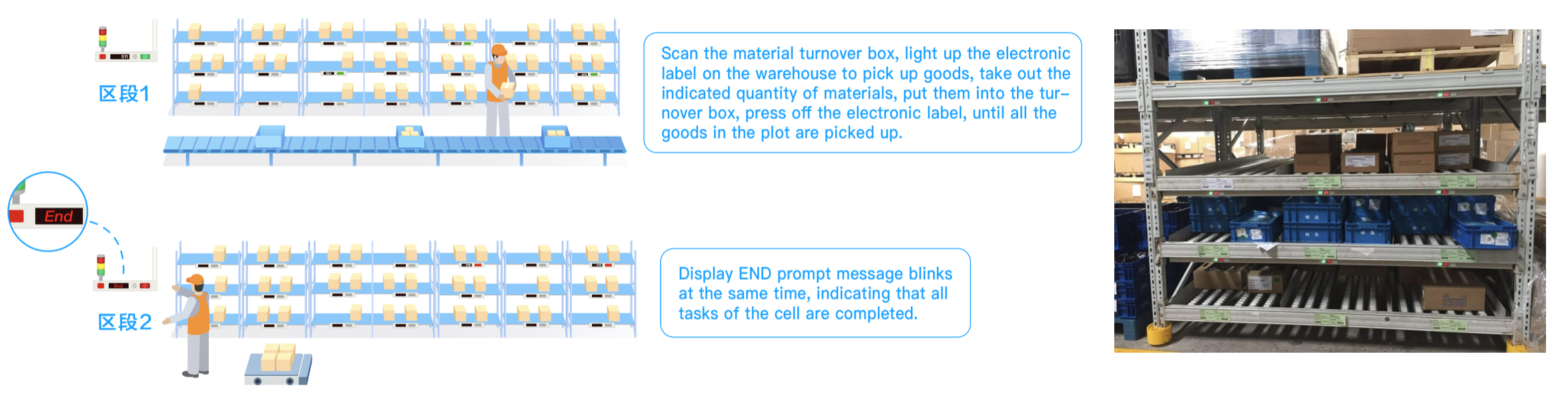

· PTL intelligent picking:

Optional order picking or multiple order combination, light to guide the material to be picked, intelligent optimization of picking path; The electronic label with LED can display the quantity of materials to be picked up for misplacing; The electronic labels for picking materials with a display screen can display pictures of materials to be picked, quantity of stock, quantity of picking and quantity of warehousing. Some labels support label operation and warehousing.

· Advantages of PTL intelligent picking

Paperless, light guide to pick materials, pick up quantity indication, pick up product indication, inventory reminder, intelligent planning of pick up path; compared with the traditional material picking, the material picking efficiency is greatly improved and the error picking rate is reduced. Reduce the skill requirement of employees and reduce the reliance on highly skilled employees for selection.

· PTL e-tag sorting system benefits

The picking speed is 30% to 40% faster than before;

Reduce the picking error rate, so that the picking accuracy reached more than 99%;

To realize the paperless operation of picking goods, the efficiency can be improved by more than 40% than the form operation;

Reasonable arrangement of pickers' routes, avoid useless walking;

Make the connection between the single channel and channel more smooth, avoid the waiting caused by adverse handover;

The system has multiple operation permissions to ensure the security of the system and database;

The system can be effectively connected with the enterprise information management system, analyze the inventory status, and can view all picking records (including operator, bar code number, picking time, no error operation, etc.;

Orders can be sorted and placed remotely through the enterprise information management system, without twice input in the distribution center;

The system product management completely adopts the bar code and other ways, so that the input is more accurate and time saved;

Operators can work without professional training, and the control software can directly import or scan the bar code to sort the goods;

Improve the efficiency of sorting, reduce the error rate to the minimum. Enable you to use limited investment to obtain unlimited benefits.

· Multi-system integrated pulling

Highly integrated with WMS, MES, ERP;

Support EDI JIS mode order release, real-time analysis and generation of pulling material list;

PTL synchronously generates mixing tasks and lights picking;

Production work order pulling, real-time pulling according to work order plan kitting mode.

· High flexibility, multi-mode optional

Many kinds of tag styles are available, including lamp, infrared and dial rod selection;

Combined with the interaction of sound and light equipment, the picking process is prompted by sound and light to improve the picking efficiency.