股票代码:833352

中文|

With the continuous growth of China's automobile output and the continuous improvement of production quality, China's automobile manufacturers in the process of improving sales and professional technology, the export of automobiles as the main target. In order to meet the requirements of national policies, automobile manufacturers are gradually changing from traditional vehicle sales to KD sales mode.For automobile KD export packaging. Due to the variety of automobile KD parts, the shape is not standard, packaging technology requirements are high, coupled with the ocean, long transportation distance, warehousing, transfer, loading and unloading, transportation and other logistics processes, in this process, there will be a variety of mechanical load, may damage the product, therefore, the role of automobile KD packaging is very obvious. At the same time, the abnormal climate change in the whole logistics process has a great impact on the internal contents, which makes the packaging of KD parts more complicated.The "parts assembly", according to the international popular saying, referred to as KD(Knocked Down) CKD (Complete Knocked Down) for all parts assembly, SKD(semi-knocked Down) is half parts assembly, part of the assembly is ready-made.

· CKD(Completely Knocked Down)

CKD is a proprietary term for imported complete vehicle models in the form of full parts. Locally produced parts are assembled into complete vehicles with lower tariffs and wages by local labor and sold at a lower retail price. At present, the introduction of China's car vehicle production enterprises or OEM suppliers in the use of all parts in the assembly line assembly into assembly or parts and inspection, testing after the factory. All parts can be imported parts or locally produced parts. Most OEM supporting suppliers now use some imported parts, some locally produced parts or all locally produced parts assembled on the assembly line into assemblies or parts.

· SKD(Semi Knocked Down)

In international trade, especially in the international automobile trade, the automobile company of the whole vehicle exporting country disassemble the finished products and export them in the form of semi-finished products or parts, and then the import manufacturer completes the finished products and sells them by assembling themselves in the host country. Using this way to export side, in addition to save freight, the use of importing country cheap labor force, but also enjoy some kind of lower import tariffs than vehicle imports, for importing countries, have to promote the development of domestic industry, and increase employment opportunities, occupy the role of the domestic market. Among them, SKD (semi-bulk parts) refers to the automobile components assembly (such as engine, chassis, etc.) basically in the form of semi-finished products are packed and exported respectively, and the importing country will assemble them locally into the vehicle. This method is introduced in The car and other vehicle manufacturers in the beginning of the way. For example, in the early stage of production, Shanghai Santana car was made in China only with tires and radios, and most of the assembly and parts were imported by SKD and assembled into complete vehicles by Shanghai Volkswagen.

Solution:

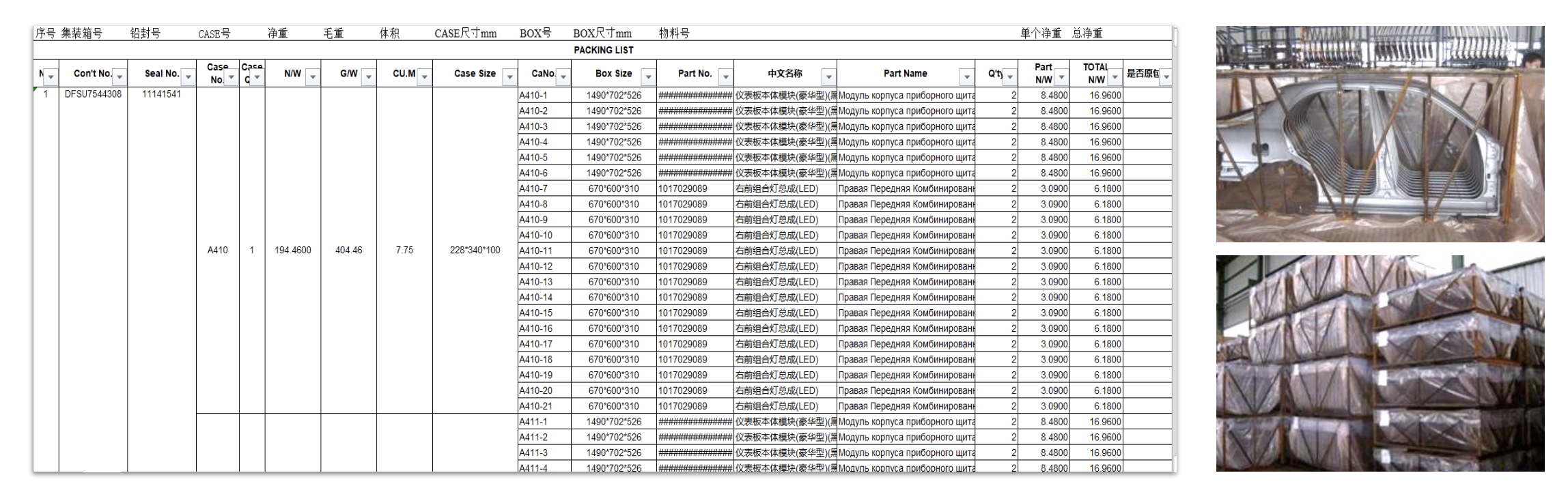

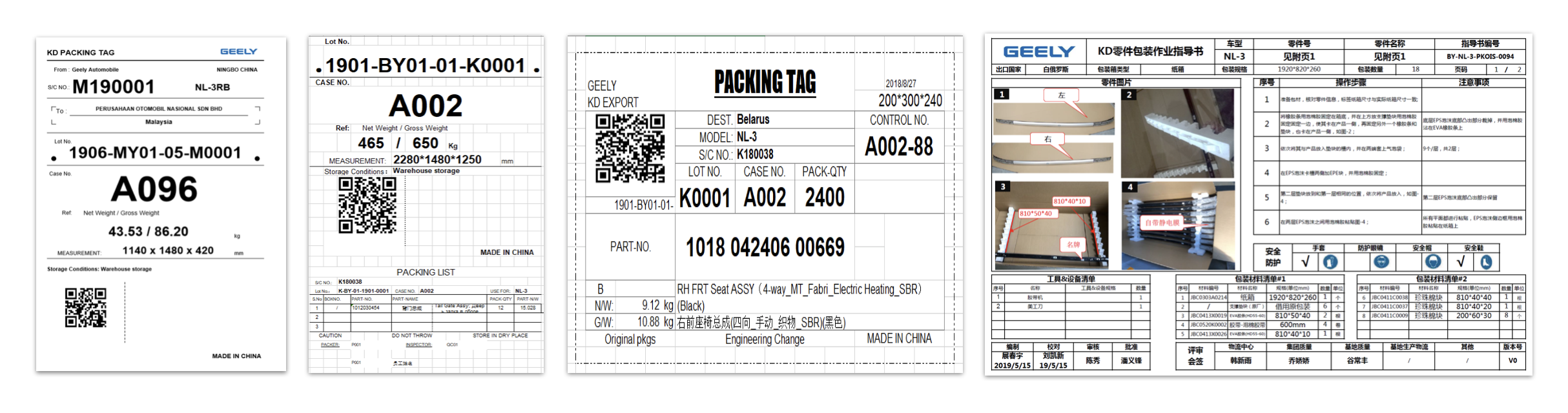

·Multi-level label management, accurate material traceability:

Automatically generate BOX labels according to the packaging schedule, and realize the fine management of storage material labels;

BOX group support is carried out according to KD packaging process and Case label is bound to realize single piece traceability;

Container packing management, multi-level label linkage, at the same time the output of customs declaration to achieve real traceability.

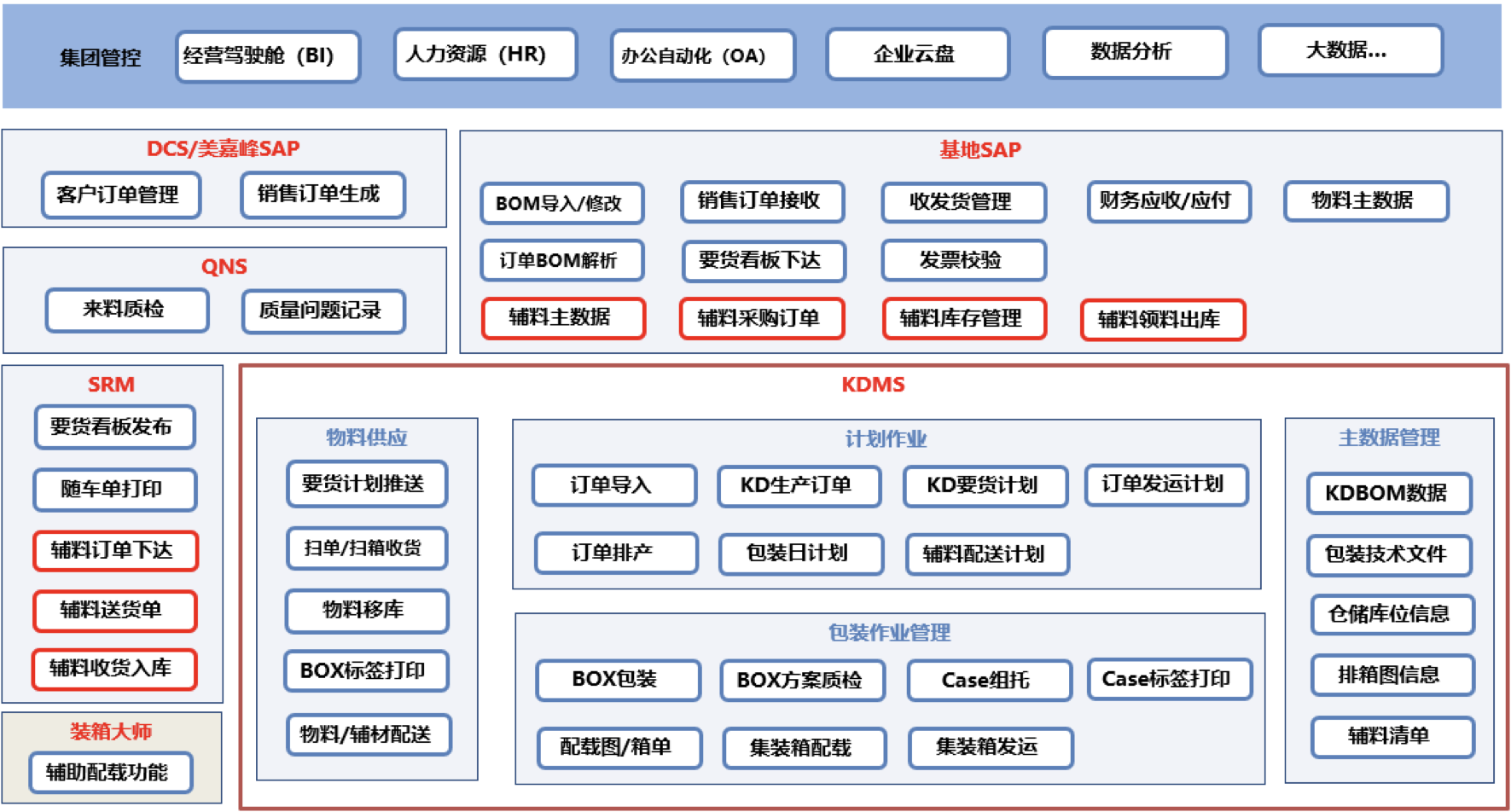

·Whole-process multi-system integration

Connect with customer EDI order system, analyze customer plan and release daily packing plan;

Connect with ERP system in real time, synchronize purchase plan of purchased parts in real time, and automatically match package day plan;

Packaging process synchronizes with QMS system to control process quality and realize real-time monitoring of process quality;

The e-SOP system is deployed in the packaging station to display the process and packaging process synchronously and guide the packaging operation online;

The TMS system is connected to bind the packaging information of container delivery in real time, to track and feedback the transportation information throughout the process.

·KD one-stop packaging service

The logistics packaging center designs the best packaging scheme and logistics planning scheme according to customers' different models and countries of shipment;

Customer KD homemade parts, outsourcing parts to the logistics center or nearby, centralized packaging;

Collect goods to the nearest port; Apply for customs clearance, book shipping space and wait for departure (by sea);

Logistics packaging center is responsible for ocean transportation, CIF to customer port;

If it involves the use of recycling appliances, will establish relevant management system for management and recycling operation;

Integrate multiple logistics links into one organization platform to reduce internal trading links and improve efficiency;

The planning of packaging scheme and logistics scheme is the source and soul of the whole logistics chain, which can be implemented and carried out in a unified organizational platform.