股票代码:833352

中文|

As the core concept of "Industry 4.0" and "Made in China 2025", intelligent manufacturing is of great significance. Intelligent manufacturing goal is to realize the intelligent of the whole value chain of manufacturing, covering research and development, process planning, manufacturing, purchasing, storage, marketing, service and so on each link, combined with information technology, advanced manufacturing technology, automation technology and communication technology, etc., latest and started into the artificial intelligence technology, emphasis on flexibility, integration, collaborative, efficient, lean, green, Put people first. To promote intelligent manufacturing is to better meet the changing needs of customers. It is necessary to fully combine the characteristics of the industry, products and processes to build a healthy and harmonious ecosystem. The I3 Plus intelligent manufacturing platform built by Eastshine based on years of experience in automobile industry informatization construction focuses on the overall planning of intelligent manufacturing architecture and the implementation of intelligent manufacturing planning scheme.

Common problems of intelligent manufacturing:

·Lack of overall planning, one-sided pursuit of automation and "machine replacement";

·The basic management level is weak, in need of a lot of "management make-up lessons";

·Informatization has not been integrated with business, there are a lot of information isolation;

·Digitization is the only way of intelligent manufacturing, but the data quality is very bad;

·Less automatic equipment, such as processing, quality inspection equipment.

Solution:

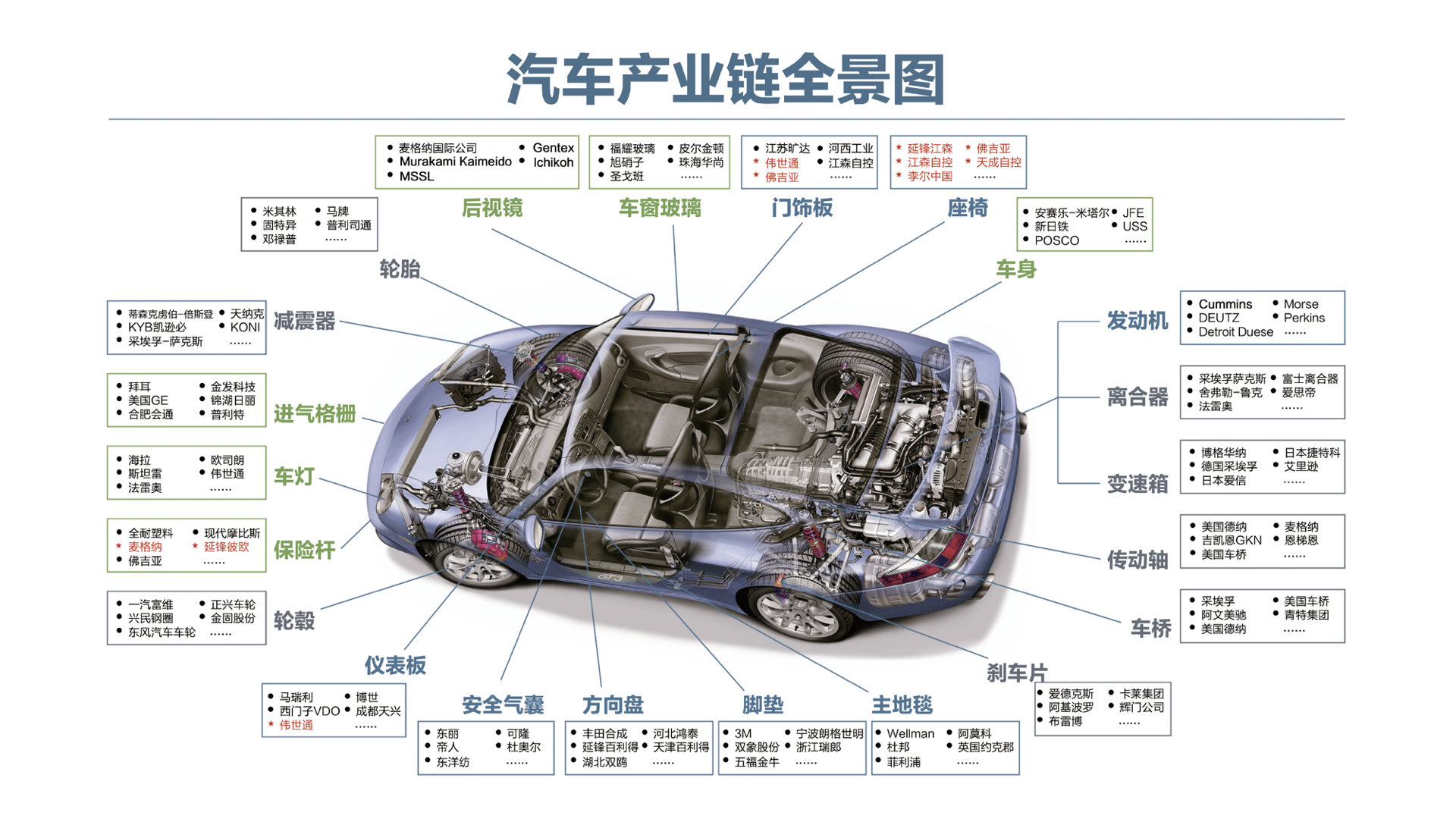

Interior and exterior finishes include:

· Body: refers to the welded assembly of body structures and coverings, including the front fins, doors, hoods and baggage compartments, which form the sealed rigid structure of the body.

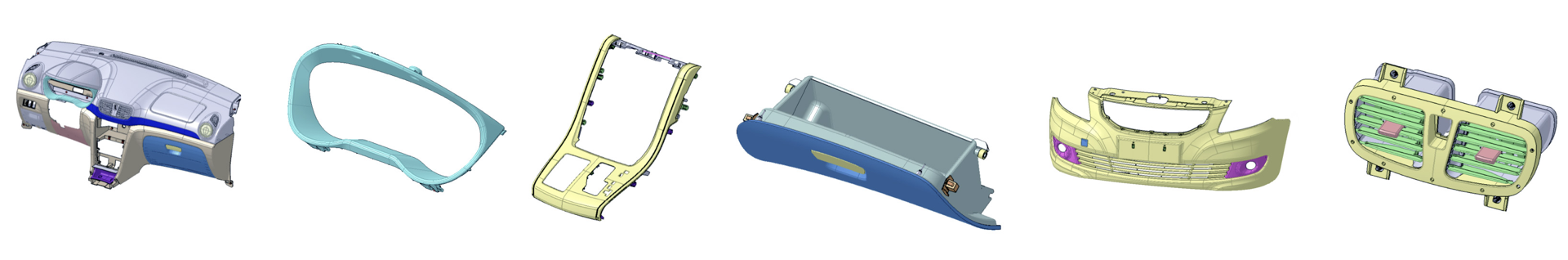

· External assembly: refers to the external parts of the car body that have protective or decorative functions and the accessories of the car body that have independent functions. The main products are: front and rear bumper, body anti-collision decorative strip, radiator mask, exterior decoration, glass, door mechanism and accessories, sealing strip and rear view mirror outside the car, etc.

· Inner parts: refers to the body interior protection or decorative role of the body, as well as the body accessories with independent functions. The main products are: instrument panel, seat, seat belt, door, roof, floor and side wall interior, sunshade, armrest, rearview mirror and so on;

· Electrical accessories: mainly including wiper, scrubber, air conditioning decoration, receiver, instrument, switch, headlight, taillight and all kinds of indicator lights, etc.

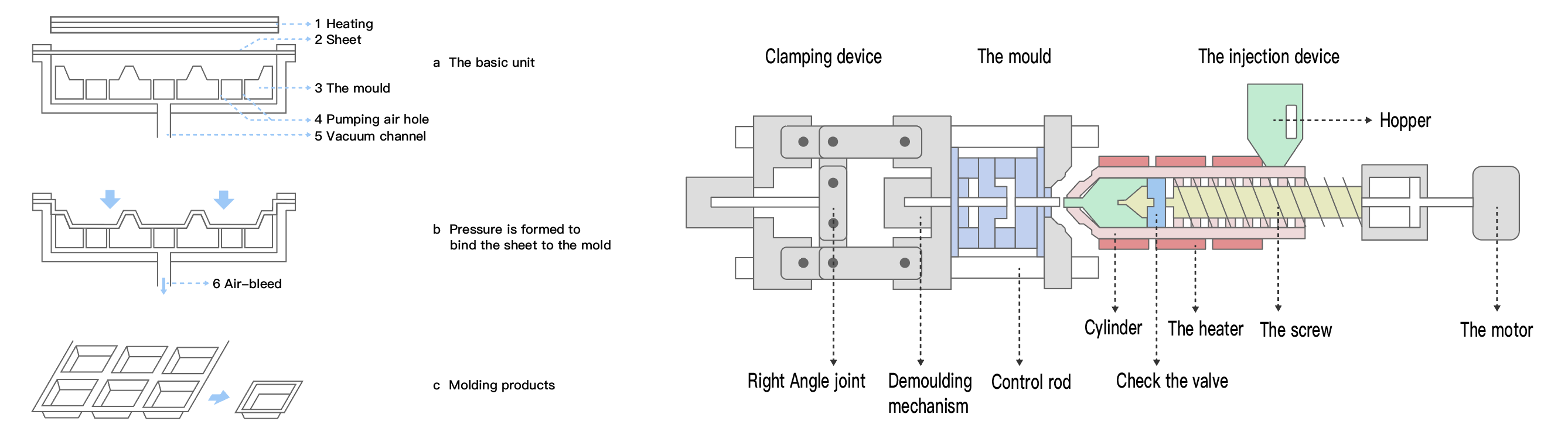

· Injection molding data collection

Injection molding can be divided into high-pressure injection molding, low-pressure injection molding, reaction injection molding (RIM) and gas-assisted injection molding.

Implement information link management in injection molding information construction, collect equipment data through PLC, and summarize production information in real time.

Process modeling according to the production process, to achieve planning, product, pouring gun, chemical material information process control.

· Production planning and mould management

Through work order management, customers' orders, work order scheduling, equipment capacity, labor, logistics and other links can be controlled by platform;

Through APS advanced production scheduling, reasonable release of production plan, timely replacement and early warning of tooling according to plan;

Chemical material batching room management, injection parts curing management, precise feeding and FIFO batch control.

· Flexible manufacturing to build a smart factory

Integrated digital control system, information control system and material storage and transportation system;

Automated switching according to processed objects;

Choose reasonable processing equipment, tools and intelligent logistics system to achieve automatic control;

According to the process and technology of product production;

Mechanical equipment can be controlled by intelligent platform;

Through modeling and platform analysis, reasonable arrangement of NUMERICAL control equipment for similar processing processes to mass centralized production, improve production efficiency.