股票代码:833352

中文|

With the rapid economic growth, the demands for commercial and trade industry, manufacturing, retailers, logistics industry and warehousing business also are increasing, with the booming of logistics and the popularity of the concept of industry 4.0, more and more customers become realize the importance of warehousing management system.Eastshine intelligent warehouse management system based on the i3 Plus platform to create a set of barcode technology, RFID(radio frequency automatic identification) technology, electronic sorting and distribution, AGV intelligent scheduling, automated forklift and other highly integrated solutions, to achieve modern warehouse lean management; Warehouse automation management, can automatically record the flow of logistics, RFID, bar code technology and information processing technology to help us make reasonable use of warehouse space,with the fastest, most correct, lowest cost to provide the best service for customers.

Problems existing in industry of intelligent warehousing:

· Goods data can not be real-time, the actual account is inconsistent with the real;

· The internal warehouse keeper is relatively decentralized, hence the cost cannot be effectively reduced;

· Cluttered accounts in the warehouse;

· It is not conducive to overall inventory planning;

· Overdue goods because not following the fifo principle;

· It is difficult to apply automation equipment if the standard is not standardized;

· A wide variety of categories, the size and specifications of the packaging of goods are very different, resulting in the intelligent equipment is difficult to adapt;

· Low level of informationize; can not realize the real time synchronization of the physical and accounting; Information become an isolated island.

· Do not defeat information integration barriers;

· Without platform support, automation equipment can not be flexibly used.

Solution:

· Standardized process design, building blocks

Flexible process building for different industries, different scales and customized business needs through process manager;

Modular flexible configuration, integrates a large number of industry service scenarios by default, meeting the requirements of different service scenarios;

Component library development mode, quick adaptation to process engine, plug and play.

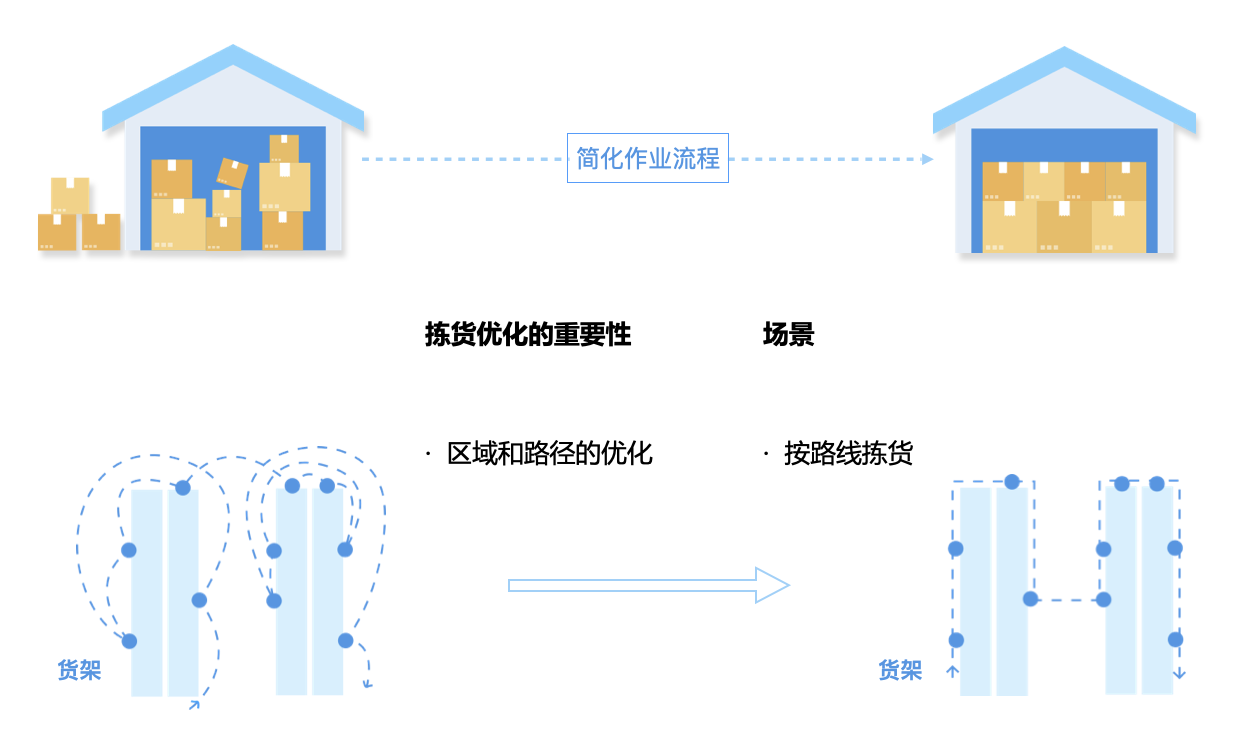

· Logistics route planning

12 attributes that can be flexibly configured

Set logistics route according to material/material group, storage type, business transaction, logistics or quality control status, etc.

Visual logistics route configuration, applicable to product classification, warehouse, product range;

Based on logistics route matching promotion rules, replenishment rules and other conditional modes;

· Strategy configuration

A variety of strategy configuration: shelf strategy, wave strategy, task allocation strategy, inventory strategy, etc., can be selected.

· Custom label/set table printing

· Dynamic interface

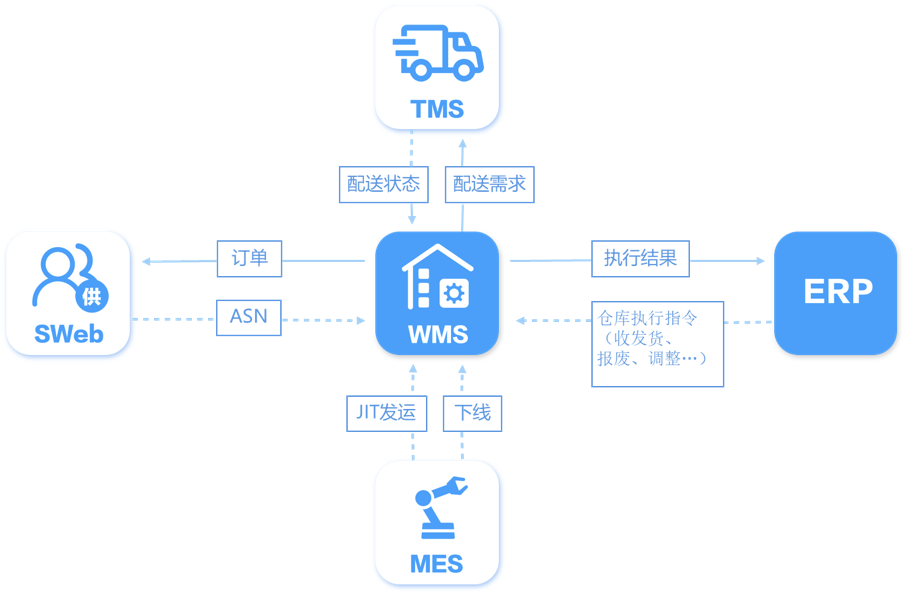

Highly integrated ERP, QMS, APS, AMP, ASRS, TMS and other systems;

Communication mode Support intermediate table, REST, Socket, message queue, WebService, FTP and other types of data transmission.

· Custom plug-in

Support Jar package, micro-service plug-in, standardized development interface, scripting personalized development and customization, plug and play, rapid deployment.