股票代码:833352

中文|

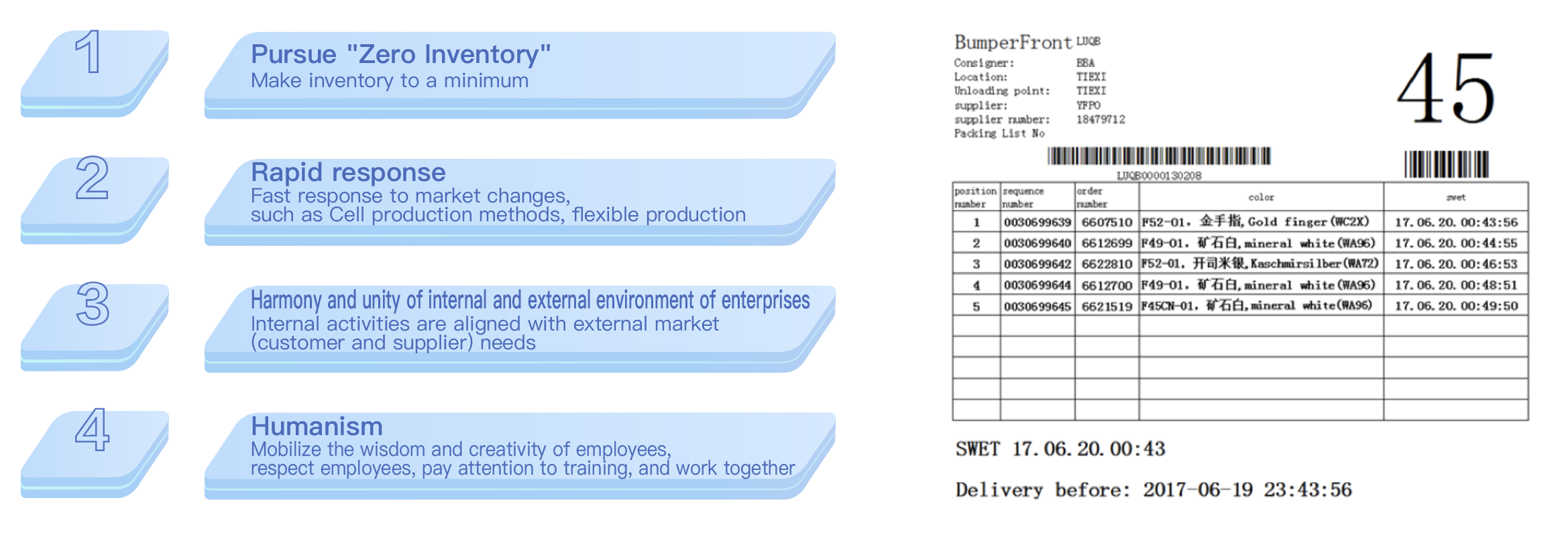

Before the just-in-time production mode was advocated, automobile factories used "all-mobilization production mode", that is, half of the time, the personnel, equipment and assembly line waited for parts, and the other half of the time, the whole staff was mobilized to produce products in an emergency once the parts arrived. This mode causes unreasonable logistics phenomenon in the production process, especially characterized by inventory overstocking and shortage. Production lines are either not started or mass production after starting up, which leads to serious waste of resources.The basic idea of JIT production is to produce what is needed only when it is needed and in what quantity it is needed, which is to pursue a production system with no inventory or minimal inventory. The basic idea of JIT is production planning and control and inventory management, and the core is to pursue a production system without inventory. Therefore, JIT production mode is also called "lean production". For this reason, Eastshine developed a series of specific methods including "kanban", and gradually formed a set of unique production and management system.

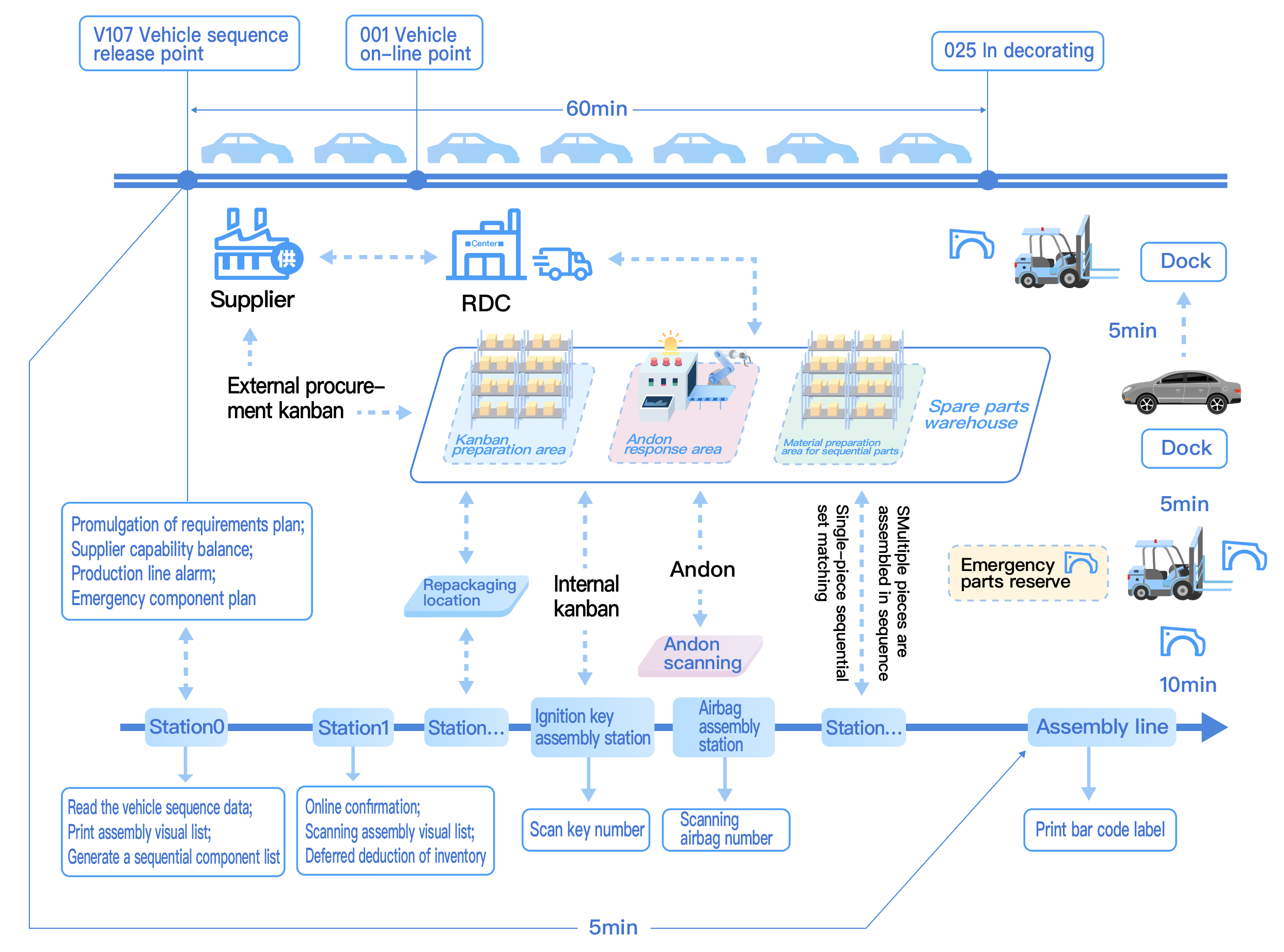

· JIS internal logistics

Optimize the logistics route;

Change the traditional way of receiving materials into the way of delivering materials;

Mass feeding will be replaced by small batch and high frequency fine feeding;

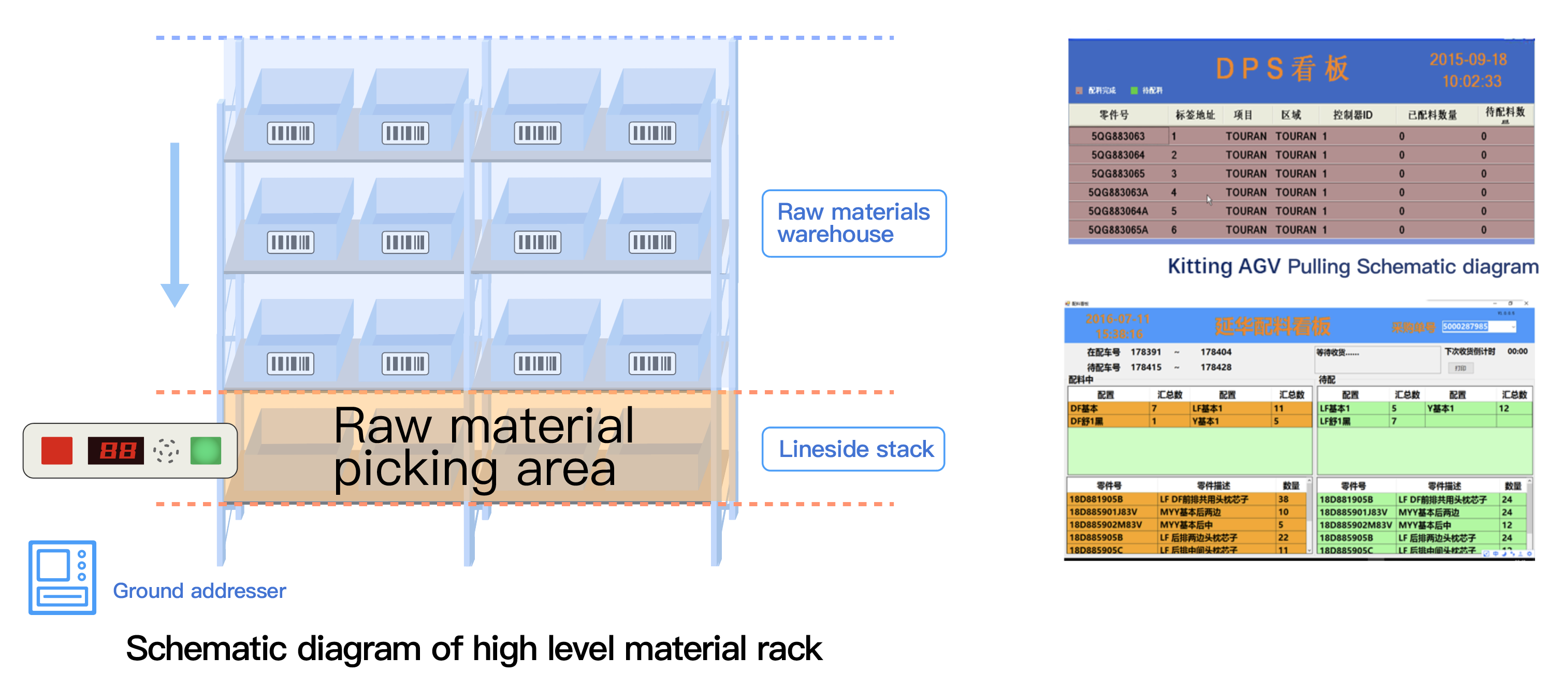

Establish material supermarket, adopt kanban pulling mechanism;

Various kanban modes match different business scenarios;

Fixed Quantity Trigger;

Trigger according to consumption;

Adjust kanban volume based on predicted usage;

Andon emergency kanban;

AGV automatic picking and distribution in sequence.

· JIS external logistics

Implement Sweb supplier management application based on i3 Plus platform to manage material pulling and distribution process online;

Receive orders from customers correctly and timely, flexibly configure EDI interface by soft adaptation engine, synchronize and analyze orders in real time;

Can complete the supply cycle within the time required by customers;

Establish effective transportation plan to deal with emergency;

Information control the whole process (production, transportation) to meet the flexible requirements of customers' production;

Prepare and pack correctly according to the requirements;

Shelf should be labeled and displayed in accordance with the regulations;

The goods will be delivered to the designated dock in the required time.