股票代码:833352

中文|

Customer requirements:

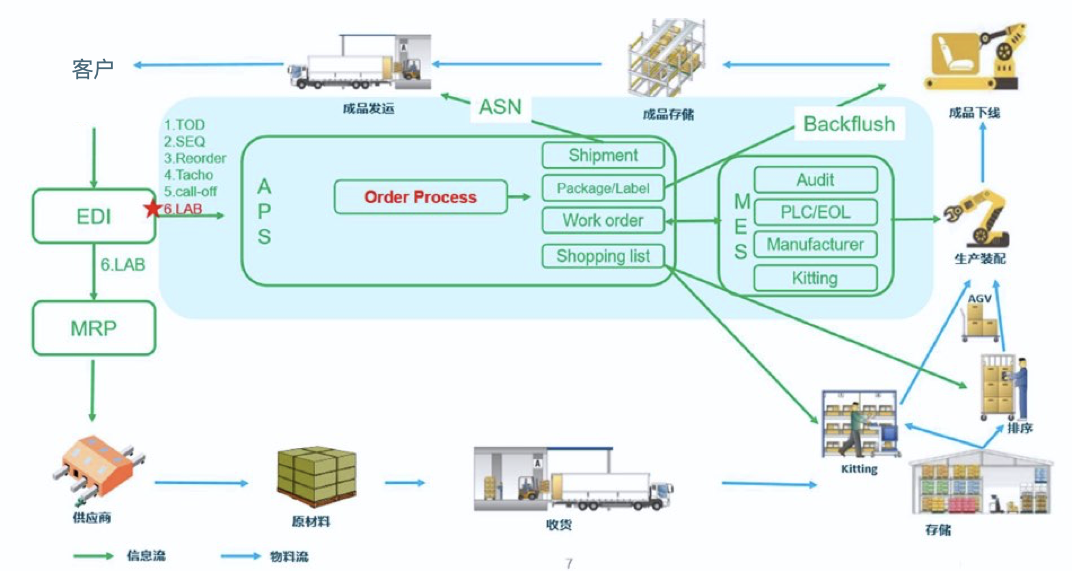

This case is a sequencing supply solution for an auto parts manufacturing enterprise in Shanghai. On the basis of EDI information, combined with production BOM structure, generate the ordering supply list of various product types (such as front bumper, rear bumper, etc.), to ensure the timeliness of the supply of parts and components suppliers of automobile OEMS. The system is developed by C++ language with the best execution efficiency. The software functions are modular, the man-machine interactive interface and the operation process is concise. Support a variety of supply pull modes: JIS5000 and JIS5300, and can be integrated with enterprise third-party systems (such as: ERP, MES, etc.). Mainly for BMW, Benz and other European brands of automobile manufacturers to provide bumper, door panels, instrument panels, steering wheel, ceiling, floor MATS, lights and other parts.

Solution:

· JIS EDI JIS Message types

Sequence Calloff: suitable for BBA JIS5000 services, which is the basis of JIS5000 ordering;

Delivery Calloff: suitable for BBA JIS5300, JIS5300 is the basis of JIS5300;

TOD: suitable for BBA JIS5300&JIS5000, need to be combined with CallOff;

TACHO: commonly used in BBA JIS5000;

ReOrder: suitable for BBA JIS5300&JIS5000 business, need to be combined with CallOff;

Sequence Information: suitable for BBA JIS5300 services.

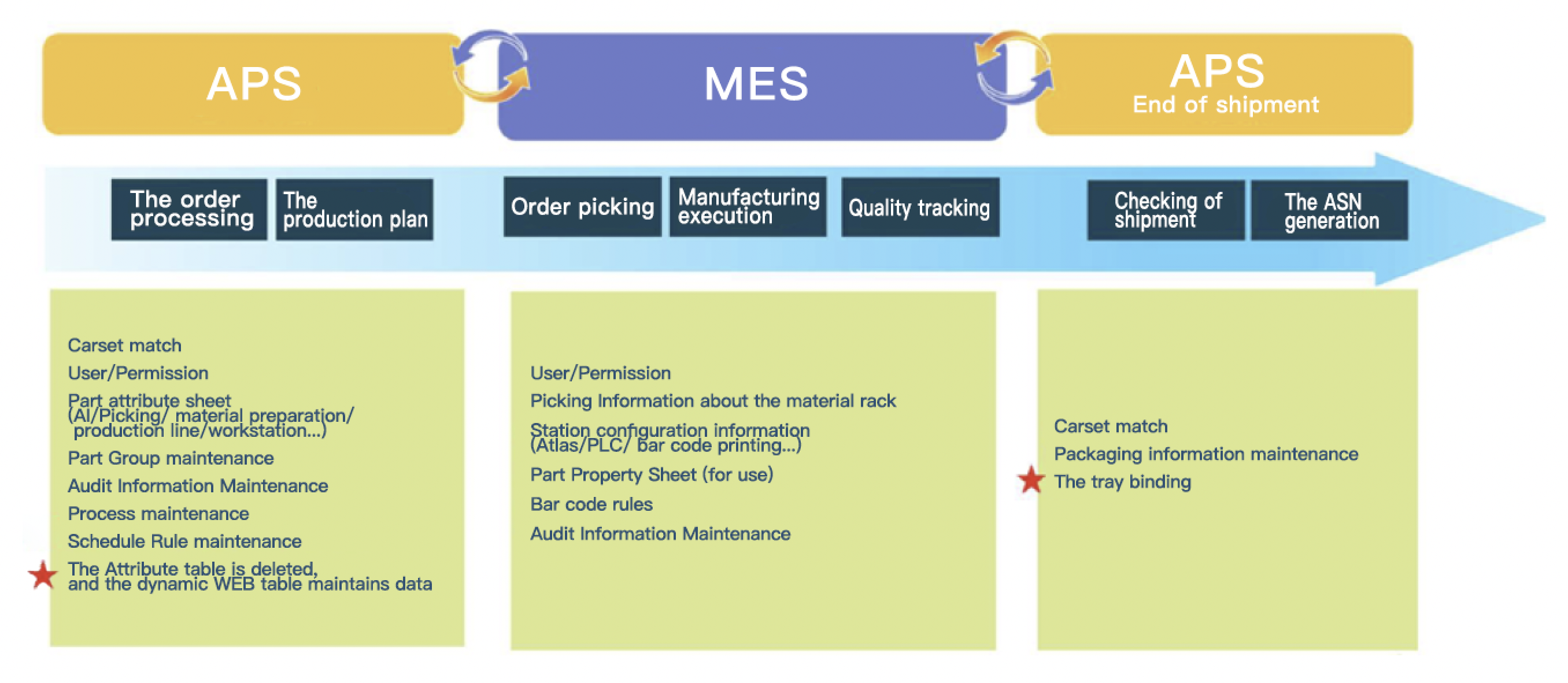

· Production planning

Get orders: get orders from EDI in a certain time range;

Work list is formed: work list can be formed according to process route decomposition;

Form the production plan: considering the possibility of capacity, personnel and materials, form the plan according to the ordering rules and optimization goals for each process;

Restrictions: each machine can only produce one work piece at a time; The next process can only be arranged after the end of the process.

· JIS order management

Automatic ordering: check whether there are unsatisfied ordering orders in the system according to the customer ordering check strategy;

The system will automatically add the newly received CallOff information to the ordering list;

The system checks whether the newly received SupplyGroup in CallOff needs to print the visual list. Print visual list if necessary;

After the newly received CallOff information is added, the system will automatically judge whether the original order is full. If the order is full, the system will automatically settle the order and print the paper order.

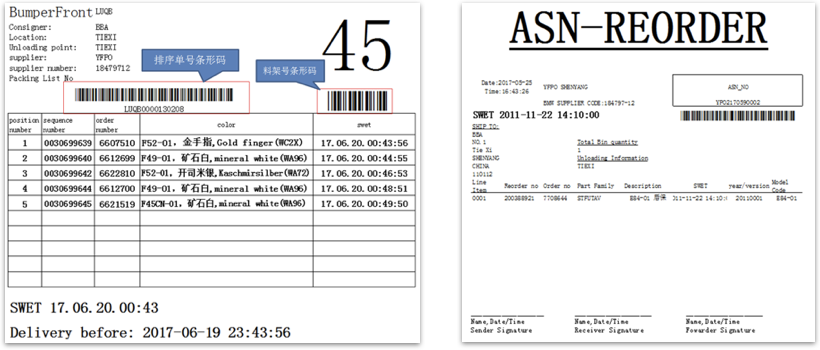

· JIS sheet/visual sheet printing

In the automatic ordering function, when the ordering list is full, it will automatically end and print the paper ordering list;

The system will automatically print the ordering list after creating it, and send it to the main engine factory along with the logistics vehicle.

· JIS order and MES interface

JIS system and MES system can interact with each other through the way of intermediate data: JIS system writes CallOff information into the intermediate database one by one, MES system reads CallOff information from the intermediate database;

The status information needs to be sent back to JIS system after the "packing check" of the sorting order is completed in MES system.

· The ASN management

The system automatically generates unique numbers for ASN orders when creating them;

The system checks the selected information when creating the order: whether the order is continuous or not;

The system automatically sends the ASN information to the third-party MES system through the interface when creating the JIS order;

The system generates and prints ASN information, and sends EDI information packets back to the OEMS automatically through the background service module.

· Querying ASN information

Users can query the past JIS order information through the function module;

Can be queried according to the generation time of the Order, the JIS order station, and the Order No;

Can reprint the JIS order list;

After JIS system generates ASN packets, the back-end module will automatically generate ASN packets needed by BBA and send them back to BBA.