股票代码:833352

中文|

Customer requirements:

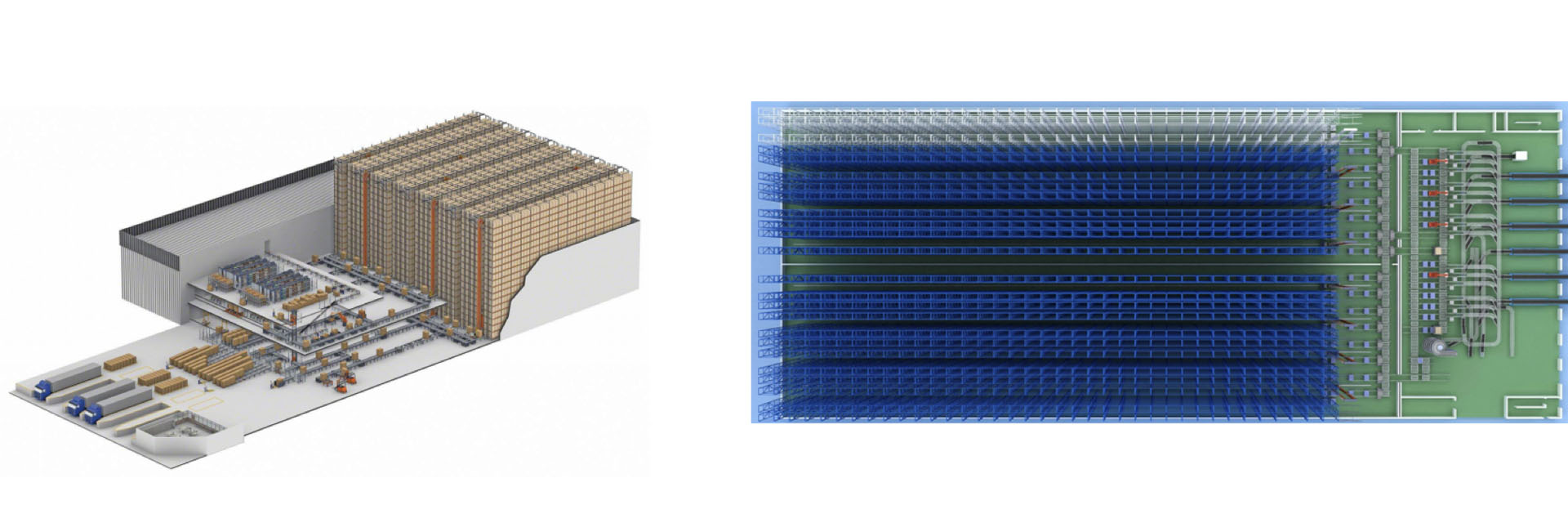

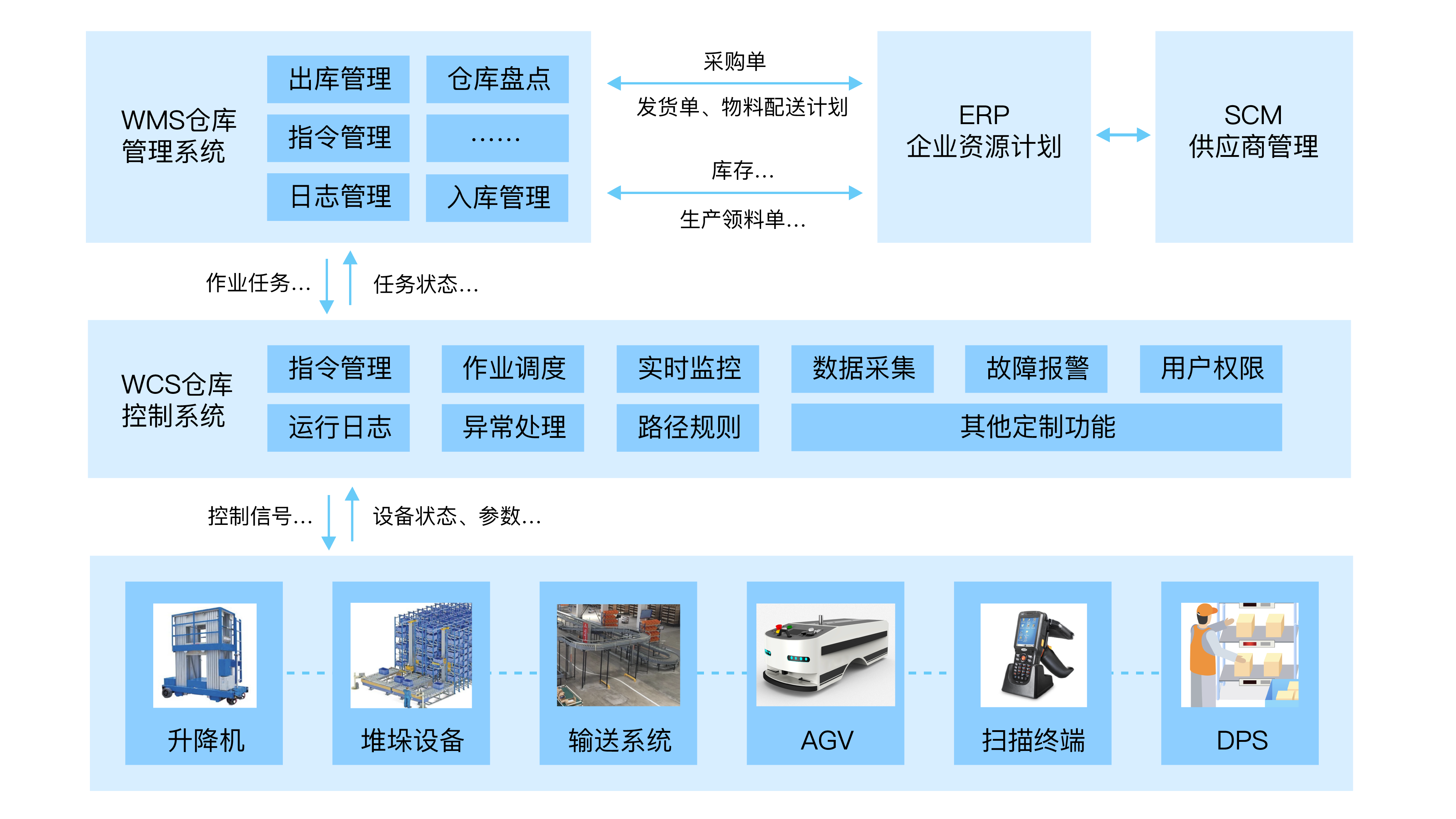

This case is to provide a three-dimensional database information solution for an auto parts manufacturing enterprise. Combined with the in-depth construction of enterprise information, the precision of warehouse management and storage efficiency of production site are further improved. The main body of the automated three-dimensional warehouse is composed of shelves, stacking cranes, in-and-out delivery section and operation control system, and with the AGV car to make the whole process more automatic, can simultaneously achieve the function of receiving, storing, taking, delivery and information storage. Among them, the operation control system is mainly composed of WCS system and WMS system, which plays a leading role in the operation of automated three-dimensional warehouse. According to the implementation of inventory management, WMS automatically generates logistics pulling and scheduling tasks, synchronizes three-dimensional database and AGV and other systems in real time to achieve efficient and accurate logistics scheduling, greatly saving enterprise inventory turnover and personnel investment, and deeply realizing the integration of warehousing and logistics information construction.

· Benefits of automated warehouse

Improve the utilization rate of warehouse space, place goods in order, facilitate inventory and search, and save land cost;

Effectively improve efficiency and release manpower, the system has the ability to quickly implement the in-and-out action, so that the warehouse can release a lot of manpower, accurate and efficient operation;

Can complete error-free receiving, acceptance, shelving, picking, rechecking, shifting, stocktaking and other warehouse operations, real-time tracking and support of warehouse operations;

Platform intelligent warehouse management, real-time task scheduling and logistics pulling, to meet the target of enterprise logistics information construction;

Enhance the overall information value of enterprises, WCS system and WMS system can quickly grasp all kinds of material information, understand the inventory situation, reasonable production and management by connecting with other information systems of enterprises.

· Automatic storage management based on RFID stereo library

RFID hardware:

Electronic label (saves the type, production batch and quantity of the object to be identified, as well as the shelf number and other information);

Antenna: transmits RF signals between the tag and the reader, that is, the data information of the tag and the command information issued by the reader;

Reader: device that reads or writes electronic label information, including hand-held and fixed type. WMS receives and processes the read label information;

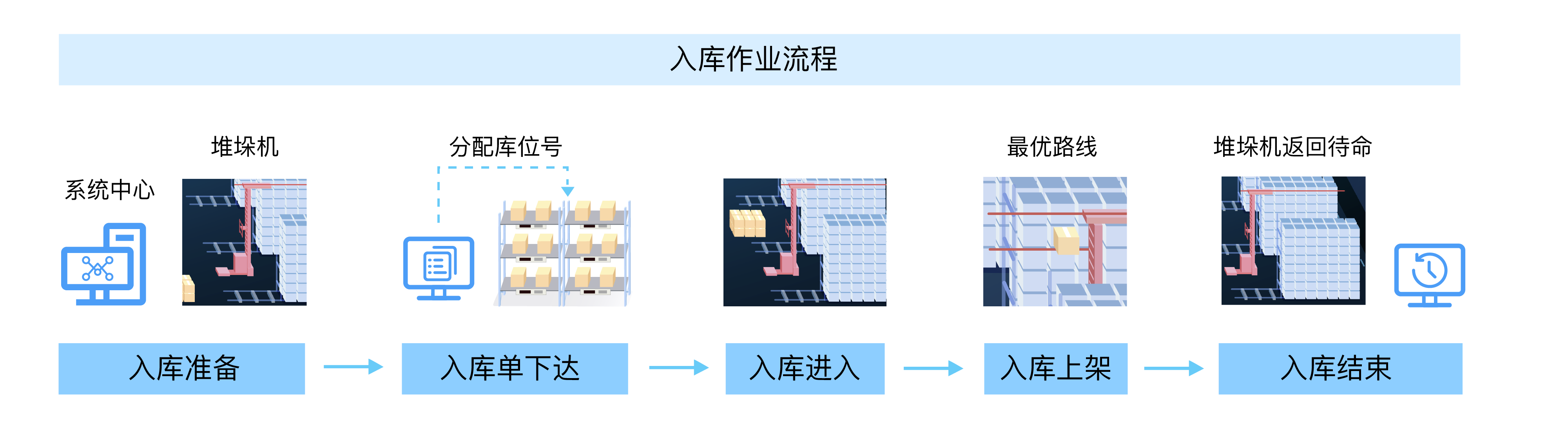

Warehousing process: ready -> order -> entering -> putaway-> ending;

The outbound work flow: outbound preparation -> outbound order -> outbound entry -> outbound shelf -> outbound end.

· Unmanned forklift truck stereo storage management

Through bidirectional information integration with MES, WMS and other systems of enterprises, the closed loop of job instructions and job feedback information can be realized, and the information flow can be synchronized with the actual logistics;

Via WMS, the intelligent dispatching system sends instructions to all the forklifts to coordinate their respective duties;

Unmanned forklifts can connect with elevators to transport materials across floors by equipped with RFID system;

Through precise route planning and safety control measures to ensure that there is no collision between vehicles, when one vehicle failure, other vehicles can be diverted.