股票代码:833352

中文|

Customer requirements:

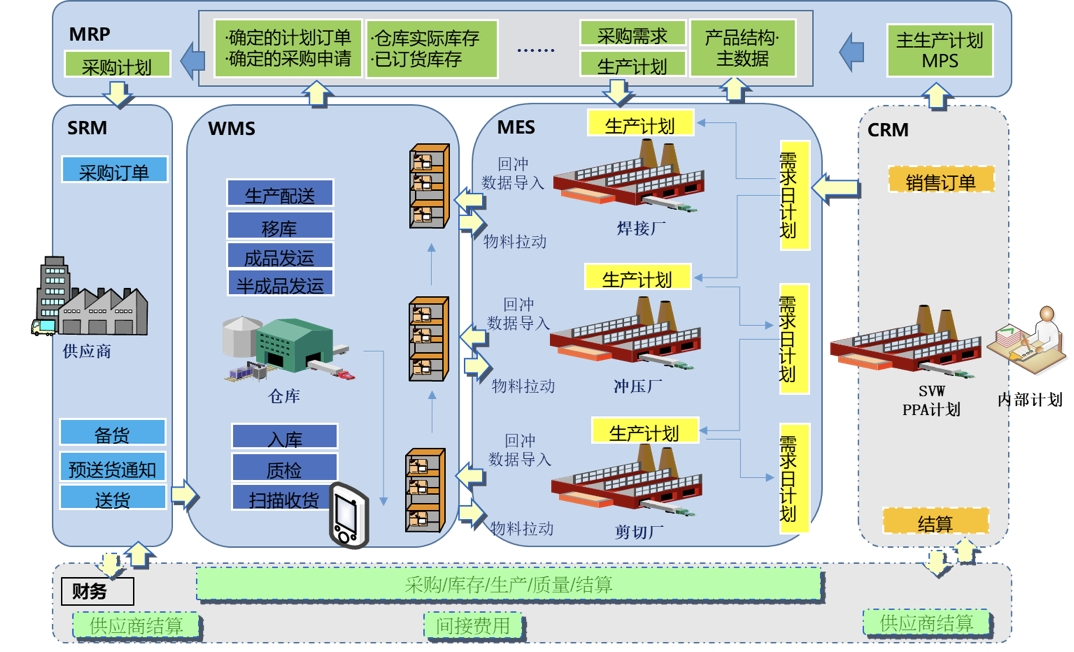

An automobile parts group affiliated to SAIC group carried out information construction and intelligent manufacturing project promotion. Based on WMS intelligent warehousing, AGV unmanned distribution and three-dimensional intelligent management, it further required to realize optimization and upgrading of supplier pulling and settlement, which should simultaneously meet the requirements of pulling and settlement among factories within the group. That is, internal transaction offline settlement (internal customers direct delivery and receipt, internal suppliers direct delivery and delivery), internal transaction ingredients settlement, pulling receipt without purchase order, external suppliers TWD\JIS pulling distribution and other modes, further reduce the factory inventory space, reduce warehouse management costs, submitted materials turnover efficiency. Combined with the construction of the platform system, the repeated investment of personnel is greatly reduced, which not only greatly reduces the personnel cost, but also realizes the intellectualization of the supply chain in the information construction.

Solution:

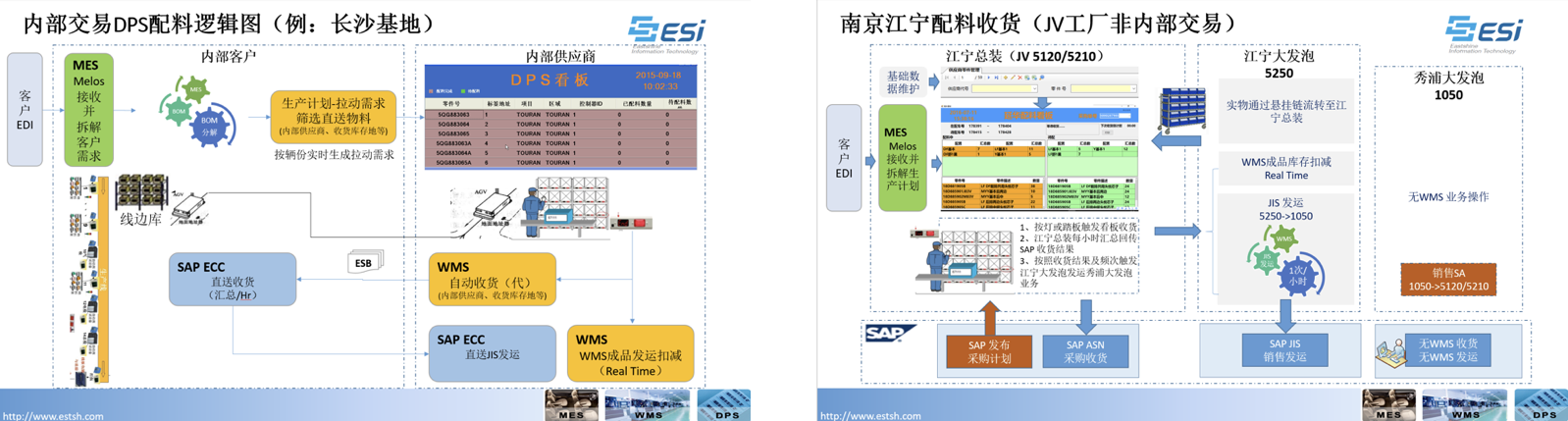

· Internal transaction

Offline settlement: the system will automatically generate the settlement task after the finished product is offline, and the procurement settlement can be realized through offline settlement;

Ingredients settlement: that is, according to the production plan to produce ingredients delivery, according to the ingredients task to achieve procurement settlement.

· Intelligent manufacturing data analysis

Manufacturing enterprises usually need to monitor, manage and analyze the data of production process, product quality and equipment operation and maintenance, and implement intelligent manufacturing management by using intelligent analysis, intelligent warning and intelligent prediction, so as to reduce physical and mental labor and greatly improve labor productivity.

· Index monitoring and data tracing

Monitor the usage of analysis indicators to check whether all analysis indicators are in use or whether someone is using indicators that others have abandoned to ensure the effectiveness of data maintenance;

Complete data link monitoring, to achieve production, quality, process and other comprehensive data monitoring and traceability, real-time control of production status.

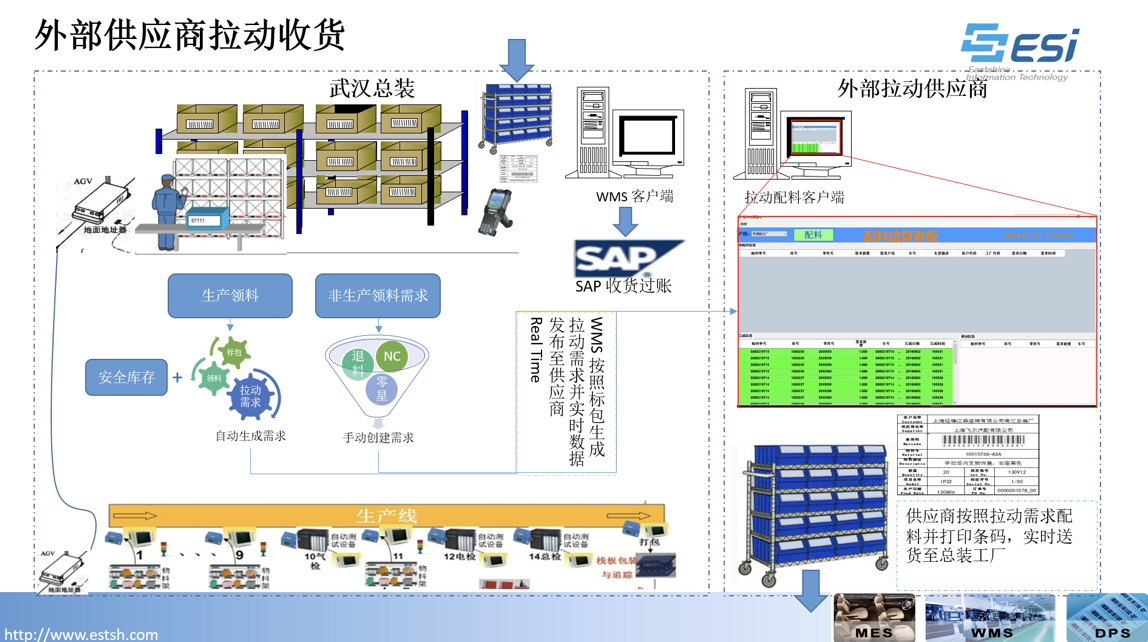

· External suppliers pulling receive

TWD pulling receive mode

-Before importing the TWD order, filter the part number list in the TWD order (remove the assembly of part_type <> 1 and part_location in (30,31)) (set as variable TWD Part List for easy reference in the following description);

-Using Part A list connect sys_part sheet, internal connect to check sys_part.batch_control=Y ‘s assembly parts list and also connect to sys_model sheet,Sys_model. model_name is the configuration of this TWD order, and the quantity of configuration is the minimum required quantity of the part list in A, which is recorded as the quantity of configuration (set as variable model_qTY);

-Associate the sys_BOM table (BOM_type = material) with b's configuration list and configuration quantity, multiply sys_BOM_detai.ITEM_count by configuration quantity (model_QTY as described in Item B), remove Part_type <> 1 and part_location in (30,31) assembly parts,That is, the list of assemblies that can be matched into the entire configuration (set as variable ModelPartList );

-The list of parts can be obtained by subtracting C. ModelpartList from A. twdpartList (calculate the difference set, consider the number of assemblies);

-Save the configuration list and quantity calculated by B and the component list and quantity calculated by D to the g_vw_TWD_detail table.

JIS pulling receive mode:

-JIS pulling by external suppliers

According to MES transfer process bar code and production sequence to produce JIS pulling sheet, delivered to the supplier for JIS pulling;

Product offline scanning process bar code report, MES will be reported to the process bar code to the pulling system;

According to the process bar code to close the corresponding JIS pulling sheet;

The closed JIS pulling sheets are packed and sent to WMS once an hour;

WMS is transferred to SAP upload PORTAL for reconciliation by day and part number summary;

JIS pulling list details (including pulling list number and process bar code) can be exported and checked from AMP supplier.

-JIS pulling from Internal supplier

Internal supplier JIS pulling parts in SAP maintained as"JIT identification";

Pulling order production with external suppliers;

In the process of offline scanning of finished products, the original internal supplier shall be used for settlement in the mode of receipt and delivery after the barcode is reported.