股票代码:833352

中文|

As an important logistics node in modern logistics system, automated three-dimensional warehouse has been widely used in logistics center. At present, the world's highest three-dimensional warehouse height has reached more than 50 meters. The storage capacity per unit area of the three-dimensional warehouse can reach 7.5(t/m2), which is 5 ~ 10 times that of the ordinary warehouse. Through high-level automation stereoscopic warehouse shelves for goods storage. The storage area can greatly to high development, in order to make full use of warehouse space and ground, this will greatly save the inventory area, improved the space utilization, at the same time due to the use of machinery and automation equipment, operation and processing speed, improve the labor productivity, effectively reduce the labor intensity of the operators. The automated three-dimensional warehouse connected with the computer management information system and the production line is now CIMS(Computer integrated manufacturing system) and FMS(flexible manufacturing system) essential key links.

Solution:

· Advantages of automated warehouse

The automatic three-dimensional warehouse adopts high-rise shelf storage and roadway stacker operation, which can greatly increase the effective height of the warehouse, make full use of the effective area and storage space of the warehouse, so that the centralized and three-dimensional storage of goods, reduce the floor area and reduce the cost of land purchase;

Automated three-dimensional warehouse can realize warehouse operation mechanization, automation, can greatly improve work efficiency;

Automated three-dimensional warehouse can realize centralized storage of materials in a limited space, which can be very convenient for temperature and humidity control;

Automated three-dimensional warehouse using computer control and management, operation process and information processing fast, accurate and timely, can accelerate the turnover of warehouse goods, reduce the cost of warehouse management;

Automated three-dimensional warehouse, because of the centralized storage of goods and computer control, is conducive to the use of modern science and technology and modern management methods.

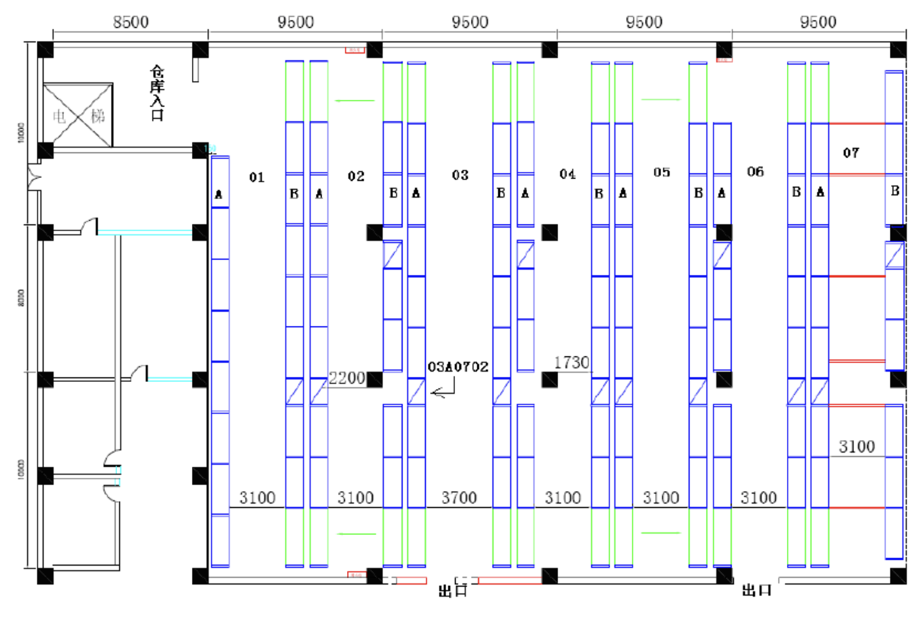

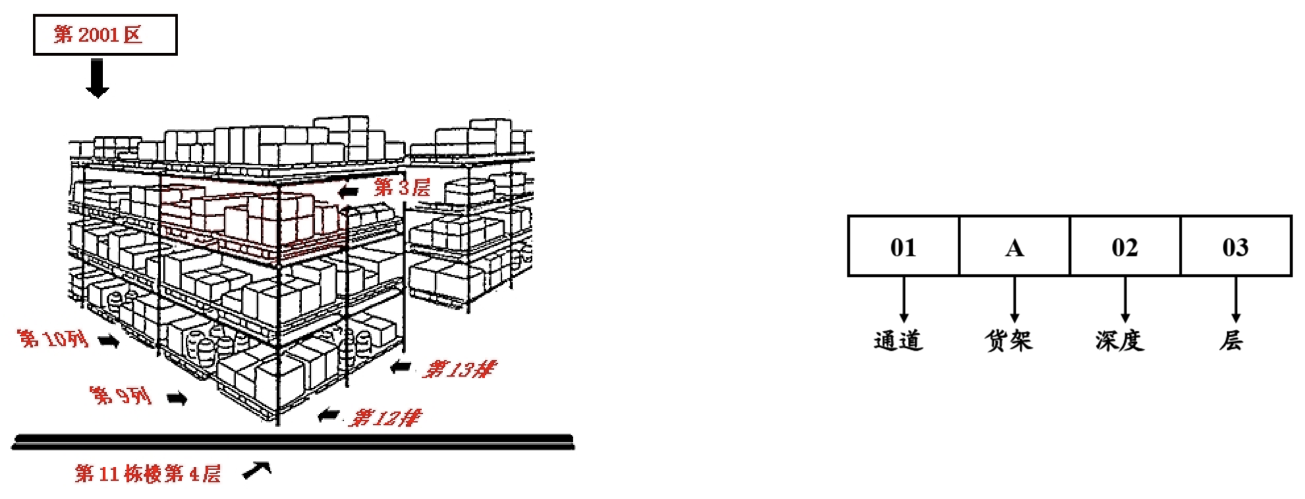

· Cargo location coding

The 1~2 places represent the channel of the warehouse, for example, the range 01-07 respectively represent the channel 01-07 of the warehouse, which can be expanded;

The 3rd place represents the two rows of shelves on both sides of the channel. The range A and B respectively represent the left and right side of the channel;

Places 4~5 represent the depth of the warehouse. The range 01~19 respectively represent the depth from 01 to 19 of the warehouse, where 01 represents the goods position closest to the exit channel of the shelf, and 19 represents the goods position closest to the entrance channel of the shelf;

The sixth place represents the shelf layer, ranging from 1 to 4, 1 represents the first shelf, 2 represents the second shelf, 3 represents the third shelf, and 4 represents the fourth shelf. The bridge shelf has only 3 and 4 layers.

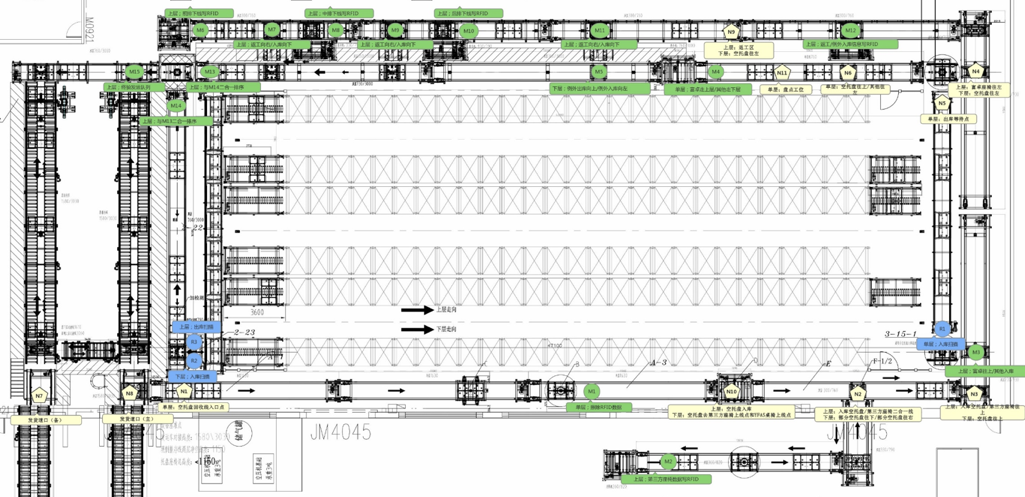

· Automation of the whole process from warehousing-in to warehousing-out

a.The automated transport of containers from the platform to the unpacking area

b.Automatic shelving of storage pallets and containers

c.Automatic moving, sending and diverting of replenishment material container

d.Automatic supply of picking goods

e.The automatic sorting machine will be implemented

· Business optimization

a.GTP job mode

b.PTL lights indicate the selection

c.Selected in advance

d.Urgently deal with high-value goods

e.Interlayer unpacking and labeling

· Make full use of limited space

a.Automated warehouse realizes intensive storage

b.Rotate shelves horizontally to create more selection points

c.Collect and supply empty pallets/bins

d.Automatic operation of reversed logistics