股票代码:833352

中文|

Customer demand:

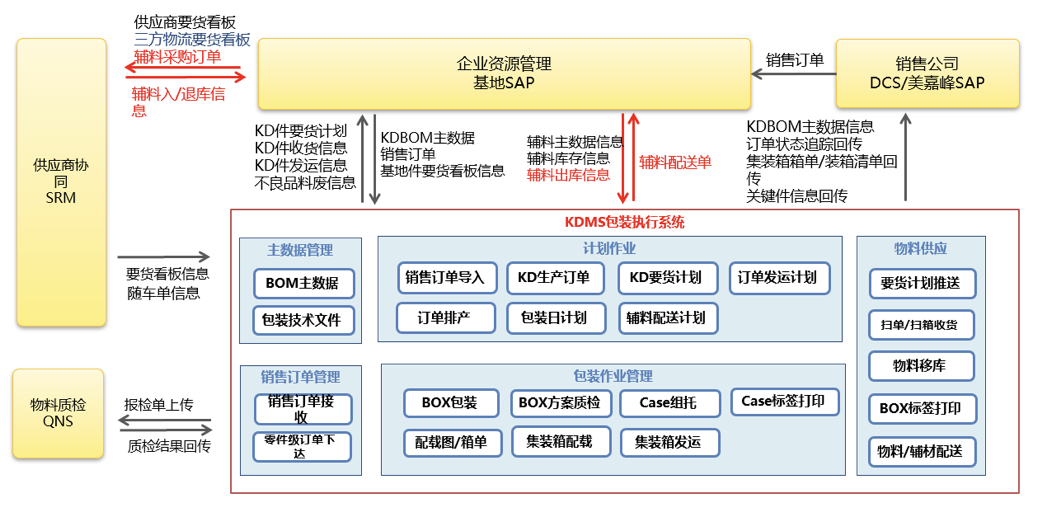

A large auto group was founded in 1986, Zhejiang province, from the production of refrigerator parts, development to the production of refrigerators, freezer, building decoration materials and motorcycles, entered into the automotive industry since 1997, has been focused on industry, technological innovation and personnel training, practice internal work continuously groundwork, unswerving promote transformation and upgrading of enterprises and sustainable development. Its total assets exceed 480 billion yuan and the total number of employees exceeds 120,000. It has been listed in the Fortune Global 500 for ten consecutive years.According to the project planning and business requirements, the business departments of this project include: Group logistics Center, Chunxiao Production and Logistics Department, Chunxiao KD packaging workshop. The corresponding business scope of each department is:

· Logistics center: responsible for the unified deployment of KD business of the Group and the formulation of standardized procedures, and the implementation of packaging technology schemes;

· Chunxiao Production logistics Department: responsible for receiving KD orders, managing KDBOM, placing sales orders and coordinating and supplying materials with international sales companies;

· Chunxiao KD packaging workshop: responsible for KD packaging business practice, packaging site management;

· IT Base: responsible for the collection of business requirements, system and network deployment and front-line operation and maintenance services.

The goal of this project is to realize the informatization of KD packaging business in Chunxiao, and take this as the pilot to form the informatization scheme of KD packaging business standard, laying a foundation for the subsequent standardization promotion to KD workshops in Beilun, Chengdu and other cities.

Solution:

·Platform product deployment to build a highly integrated application service system

The platform integrates ERP, AMP, ASRS and AGV. Automatic scheduling QMS, TMS and other information products, fully break the information barrier, realize the data immediately available;

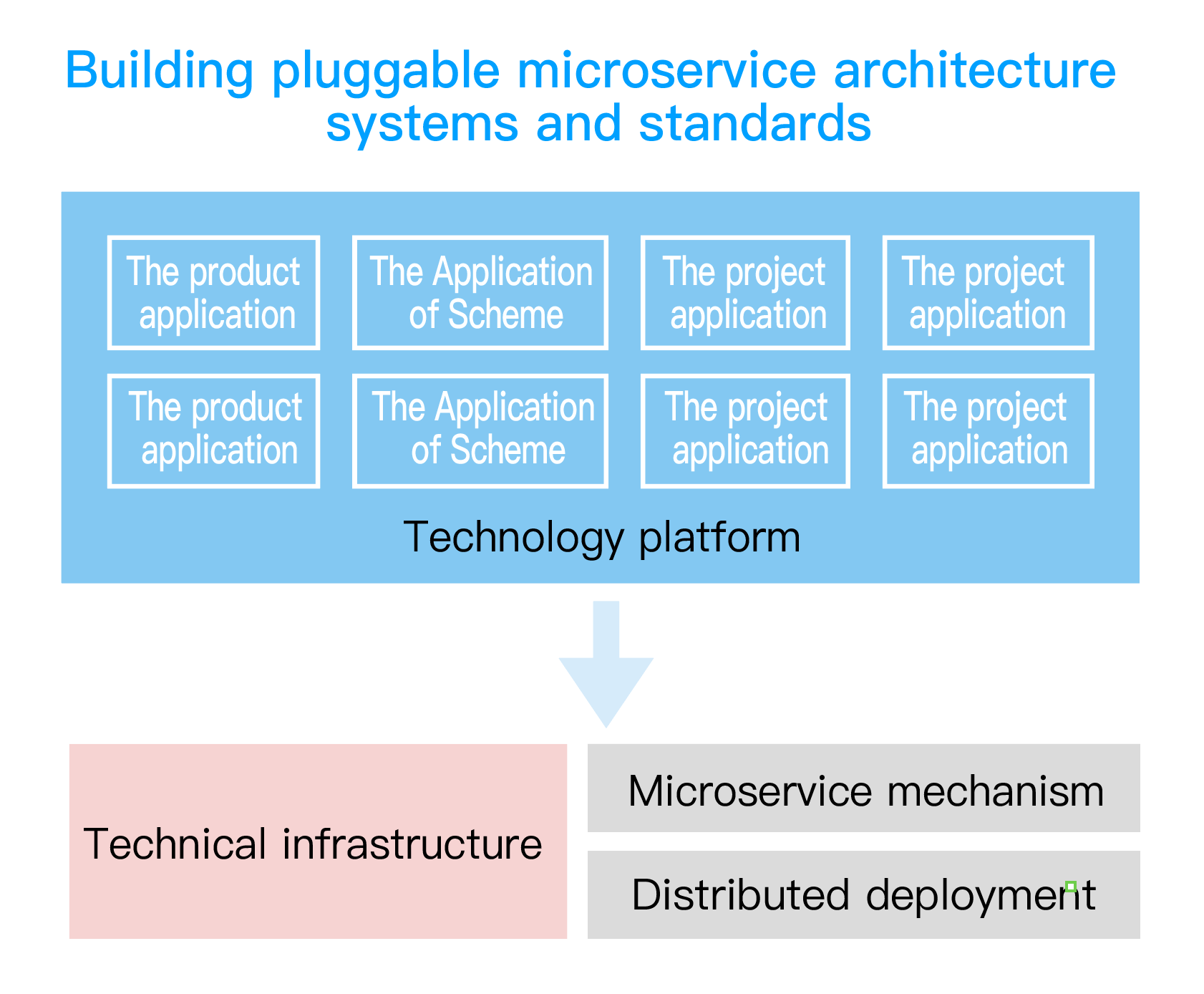

·Adopt microservice mechanism

Adopting micro service mechanism, the service architecture is a kind of to a single application development as a set of small service method, each service in the process of operation, service communication using lightweight communication mechanism (API) usually use HTTP resources, these services around the business ability to build and deployment by automatic deployment mechanism independence.

·Introducing MQ message queuing

Eliminate the process of polling so that clients can receive and retrieve new messages in a timely manner;

The client uses MQTT protocol to communicate with the server and supports different types of clients;

Messages can be sent in a variety of ways: in-site letter, email, wechat, smart devices, etc.

· Business process engine, visual business process configuration

Service processing, service operations can be configured, pluggable;

By dragging and dropping service components, flexible configuration of service processes can be realized.

· Fine management of raw material inventory

Warehouse management of purchase parts, synchronous SAP purchase order information and mobile terminal scan and receive goods;

Self - made parts warehouse management, daily packaging plan production and print Box labels;

According to the material packaging agreement, print Case labels and bind Box labels and pallet labels to achieve accurate single piece traceability;

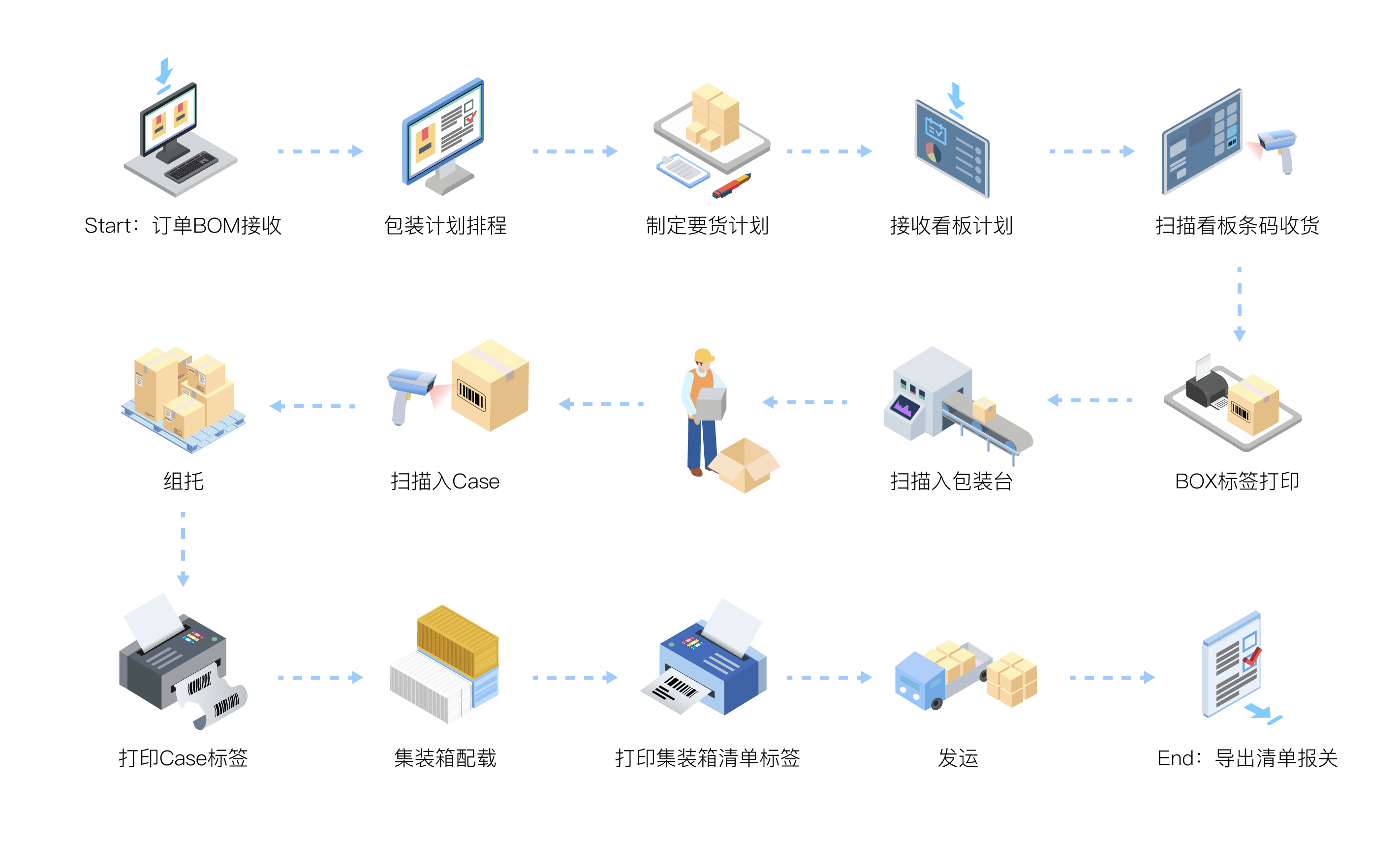

· Multilevel packaging process management

Through EDI interface docking, automatically receive and parse customer order plan;

Automatically calculate daily packing plan and release packing task to packing station according to packing capacity and inventory of production line;

Packaging station use management system, online synchronization of packaging technical specifications, system scan labels and verify the integrity of packaging process.

· Packaging product traceability management

Through multi-level packaging, the system realizes multi-level label binding, box label -> pallet label -> cage/container label;

Automatic generation and printing of packing list, by scanning labels to achieve accurate traceability;

Synchronize customer delivery plan, generate delivery list and customs declaration, accurately control and reduce transport loss.