股票代码:833352

中文|

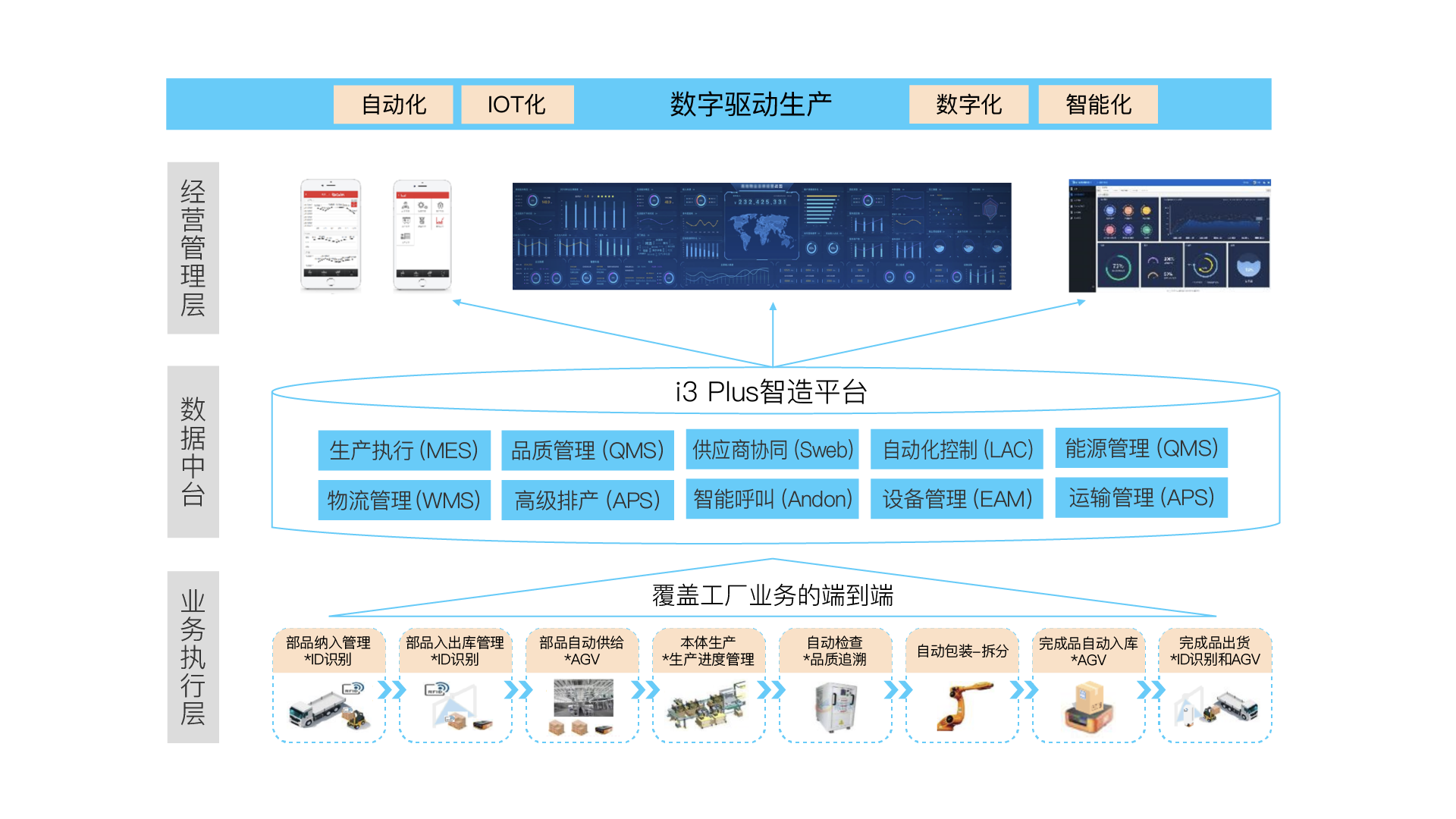

An electronic housing equipment machinery (Hangzhou) Co., LTD., founded in 2004, is a wholly owned enterprise of a Japanese electrical industry corporation. It is an important overseas production base of the electronic housing equipment machinery group, which mainly produces white appliances. Specializing in the development, production, sales and services of electronic seat covers, vacuum cleaners and other household appliances and other residential equipment, machinery and components and supporting products. As the world's leading manufacturing enterprise, it is necessary to introduce intelligent factory construction in order to lead high-end manufacturing, provide customers with better high-end products, meet high-quality production and manufacturing, achieve lean production, improve the efficiency of production, storage and logistics, connect upstream and downstream, coordinate management, increase efficiency and reduce cost and other factors. With the help of Eastshine's proven I3 Plus intelligent manufacturing management platform, we can help customers build fully convenient intelligent factories. Achieve automated production, production IOT, numerical and intelligent production, ultimately through digital driven production, bring about the transformation of production and operation.

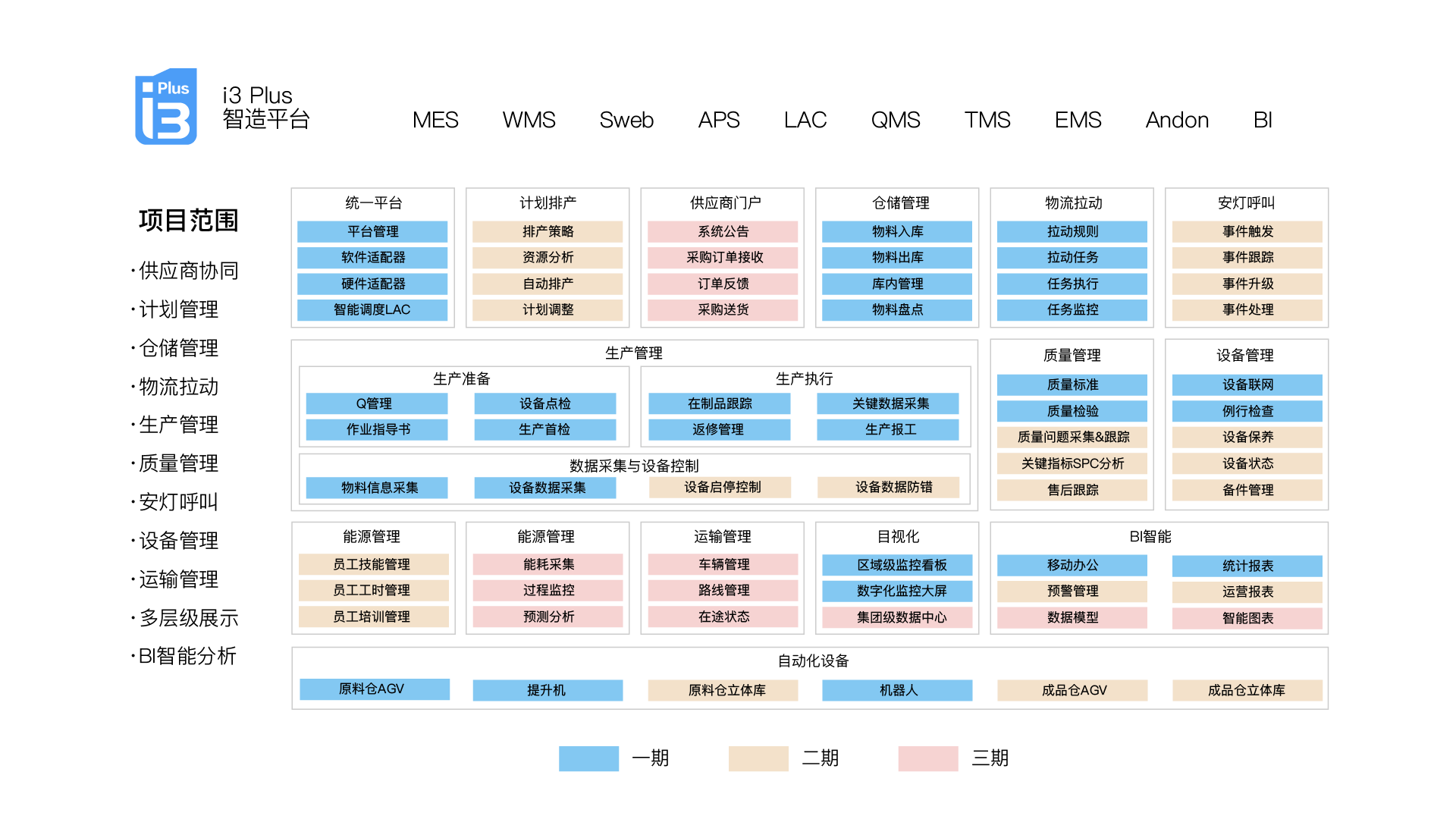

Scope and functional modules of this project implementation

Overall preview of the revamped business

· Establish BI and PMC big data intelligent analysis platform

Cross-system data integration: data covers operational KPIs, quality performance, manufacturing execution, exception management, equipment management, finished product and raw material management, etc. Data were collected from ERP, MES, WMS, Andon and other systems, and presented as business demand data after big data analysis and calculation.

Real-time onsite data display: The collection of on-site manufacturing information and real-time monitoring of data can be obtained. it also includes small changes in the manufacturing process so as to avoid risks in the bud. On the basis of monitoring, real-time analysis of the factory big data platform can be more intuitive and profound to understand the operation of the site.

Auxiliary decision: visual data includes five field elements of man-machine-material-method- interactive means can be used to dynamically obtain the data needed for decision-making in real time, providing real and comprehensive data support for operation decision makers.

· With the pilot of an industrial park, the whole group architecture design, the group multi-level architecture, diversified business mode system deployment.

· Adopt Ali-cloud deployment, reduce the massive input of server hardware.

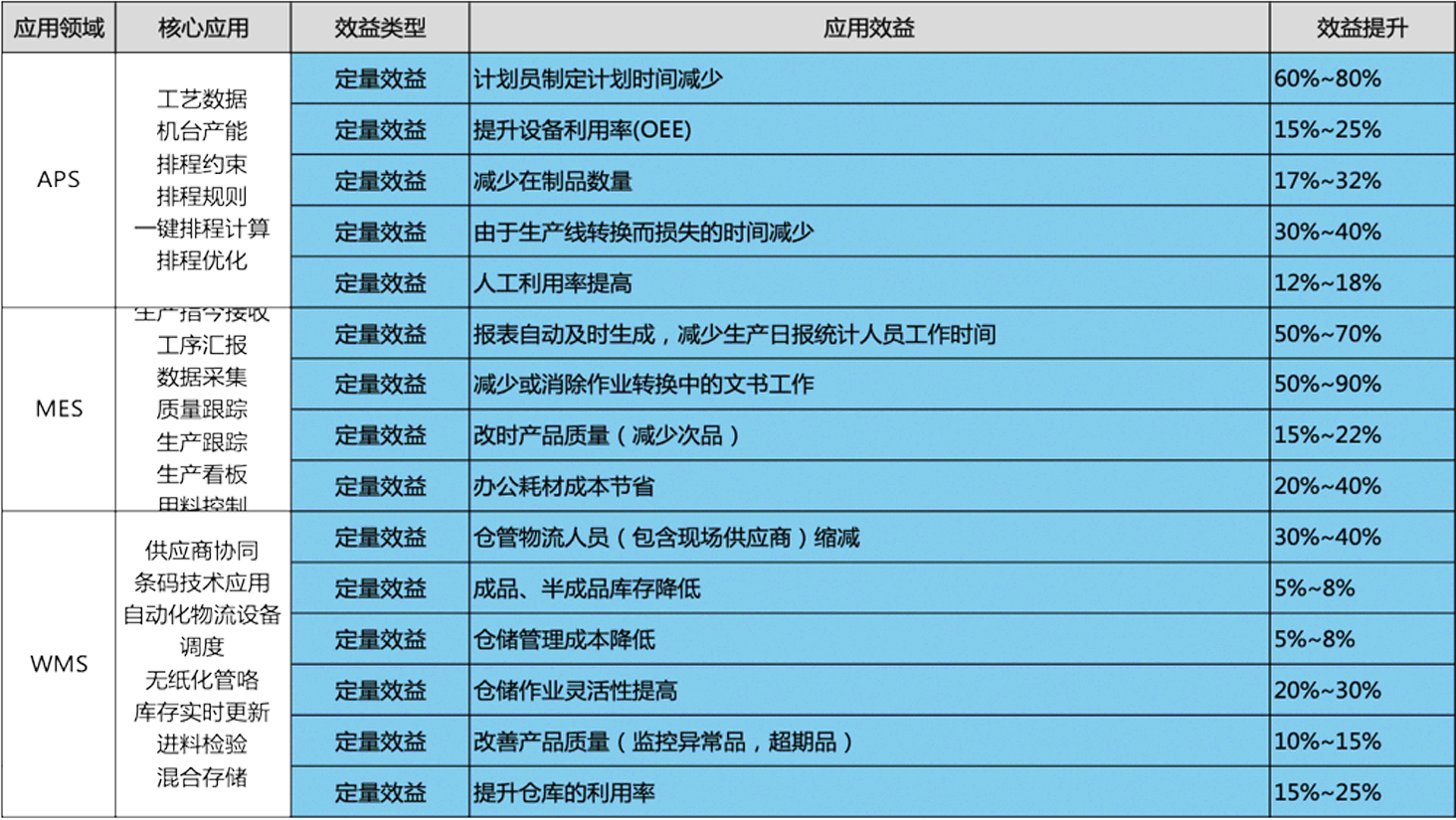

· Efficiency gains.