股票代码:833352

中文|

Customer Introduction:

Atlas Copco is a world leader in compressors, expanders and air handling systems, construction and mining equipment, power tools and assembly systems. Through innovative products and services, Atlas. Copco offers a variety of solutions for sustainable productivity. Atlas Copco was founded in 1873, headquartered in Stockholm, Sweden, with a global presence in more than 170 countries and regions. In 2010, Atlas. Copco employs about 33,000 people and has a turnover of seK 70 billion (7.3 billion euros).

Customer requirements:

Due to the lack of perfect storage location management in THE SAP-ERP system and the lack of flexible and effective planning and guidance for materials in and out of the warehouse, all business departments cannot work together effectively. As a result, the material model system is unscientific, the warehouse business efficiency is low, the reasons for errors cannot be found quickly and the most critical warehouse material status cannot be reflected in real time.

Workshop production site material multi - collar, wrong collar, lack of materials and other phenomena occur from time to time, resulting in disorderly production site, high manufacturing cost, workshop station material guide can not be very good control (as long as the guide opens the material list, the warehouse keeper will send materials). It is hoped that the system can automatically produce the forward material issuing list according to the production scheduling and guide the custodian to carry out the material issuing.

By taking charge of the goods in the material warehouse, it can effectively manage the inventory in the Atlas warehouse stored by suppliers, and at the same time, it can not stop production without materials in the workshop. At the same time to solve the material FIFO warehouse, improve the efficiency of warehouse keeper to SAP manual input and so on.

Although weekly production plan is used as production guidance, the status of the implementation plan of the whole workshop is not available, and the decision maker obtains the production process information from the workshop personnel. How to track wIP production process and obtain real workshop status information in real time (plan execution, production status, etc.) so as to adjust business strategy in time has become an urgent problem for company leaders.

System functions:

· All-round management of products

· Quality inspection management

· Product warehousing and material distribution

· Warehouse return and inventory

· Inventory warning and quality traceability

System benefits:

· Timely data collection, precise process management, fully automated intelligent guidance, improve work efficiency;

· Precise location management, comprehensive status monitoring, make full use of limited warehouse space;

· Shelves and shelves are automatically allocated according to fifO to avoid human error;

· Real-time control of inventory, reasonable maintenance and control of enterprise inventory;

· Traceability of product production or sales process through automatic collection of batch information.

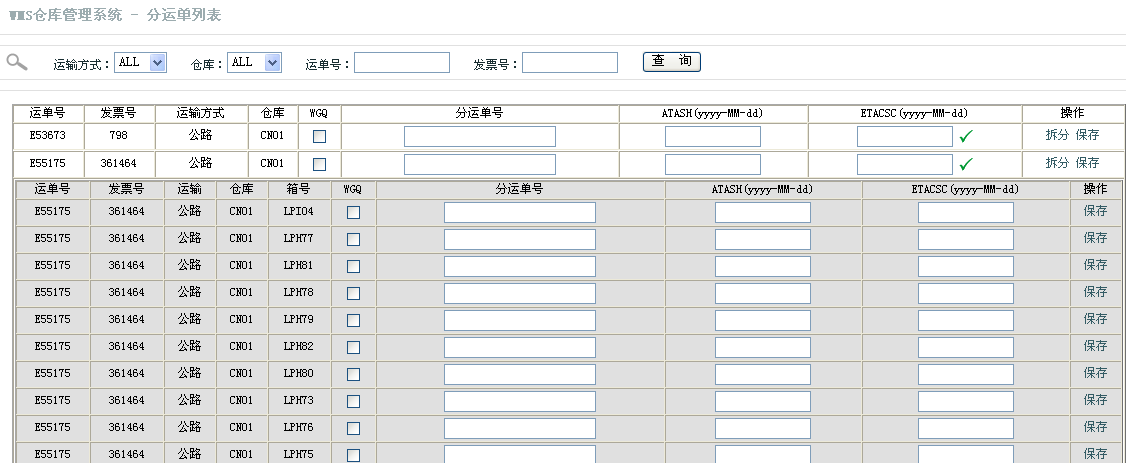

System interface: