股票代码:833352

中文|

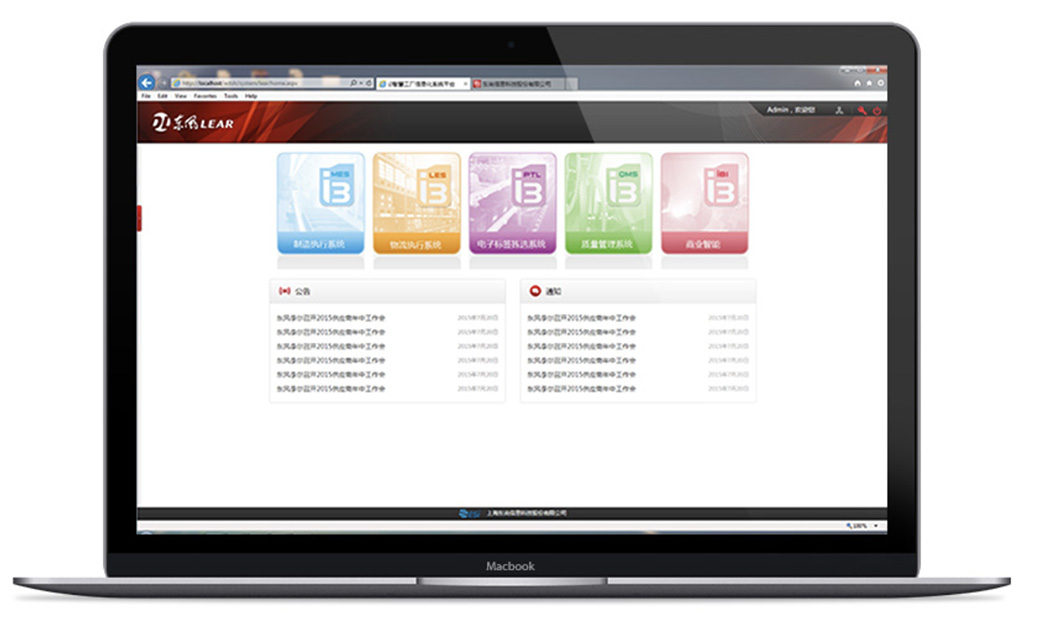

The intelligent factory information management system based on Industry 4.0 is basically comprised of five innovations including mobile computing, social media, Internet of Things, big data, analysis and optimization prediction. Individually, they all have huge potential for business and reform. Increasingly, they are used to enhance the interactivity between today's systems. At the same time, each system can influence and exchange information. Through this innovation leap, enterprises can become the industry leader of intelligent networked products and production systems. In thinking of their totality and integration, they contain the potential for a fourth industrial revolution.Dongfeng Lear Car Seat Co., Ltd. is one of the important suppliers of car seats of Dongfeng Motor Company, wuhan headquarters for passenger cars, DpCA, Renault, Dongfeng Honda car seat production base. The intelligent factory information system platform created by Dongfeng Lear and Shanghai Eastshine, based on industry 4.0 planning, realizes the comprehensive informationization of the factory, making the future digital factory realize real-time data, information visualization, paperless system and intelligent manufacturing. Finally, smart factory equipment based on industry 4.0.

Eastshine Information has many years of experience in system planning and implementation of auto parts industry. As the system integrator, Eastshine information laid a solid foundation for system implementation together with the FACTORY IT department from production network planning and server selection to specific network implementation.

The smart factory program includes EDI (Customer data exchange interface), production Execution management system (MES), warehouse management system (WMS), quality management system (QMS), security lighting system (Andon), supplier management platform (Sweb) and the design and implementation of all systems with ERP (QAD) interface. The implementation of SWEB makes the response of suppliers to the purchase plan more controllable. In this way, the raw material inventory and the process of personnel processing are well controlled.

MES is used in the production process to make the production process controllable to meet the requirements of customers in all aspects of production management. Moreover, through the interface with WMS and QMS, the production data, quality data and raw material data can be traced. Finally, through the analysis of the data layer, accurate, reliable and timely data are provided to the decision-making layer of the enterprise as the support of decision making.

Interaction and management with production line automation equipment, testing equipment, robot equipment, AGV equipment and delivery line equipment make the system really play the "brain" role of production management. At the same time, various electronic kanban boards such as production kanban board, supplier kanban board, quality kanban board and energy system kanban board are used to display timely data to different levels.