股票代码:833352

中文|

Customer requirements:

MAGNA has formed a joint venture with Beijing HAINACHUAN Auto Parts Co., which already has a door module business with a German automaker in China. In order to meet the rapid development of the market demand, the joint venture has decided to build a new factory in Beijing area.The door module production line of a factory of MAGNA in Beijing provides finished door modules for high-end models of a well-known brand. The process is relatively complex and requires high quality and timeliness. According to the needs of the factory, Eastshine Information developed an overall plan covering all aspects of workshop manufacturing from production scheduling to finished products delivery for a MAGNA Beijing plant after a lot of detailed research in the early stage.

Solution:

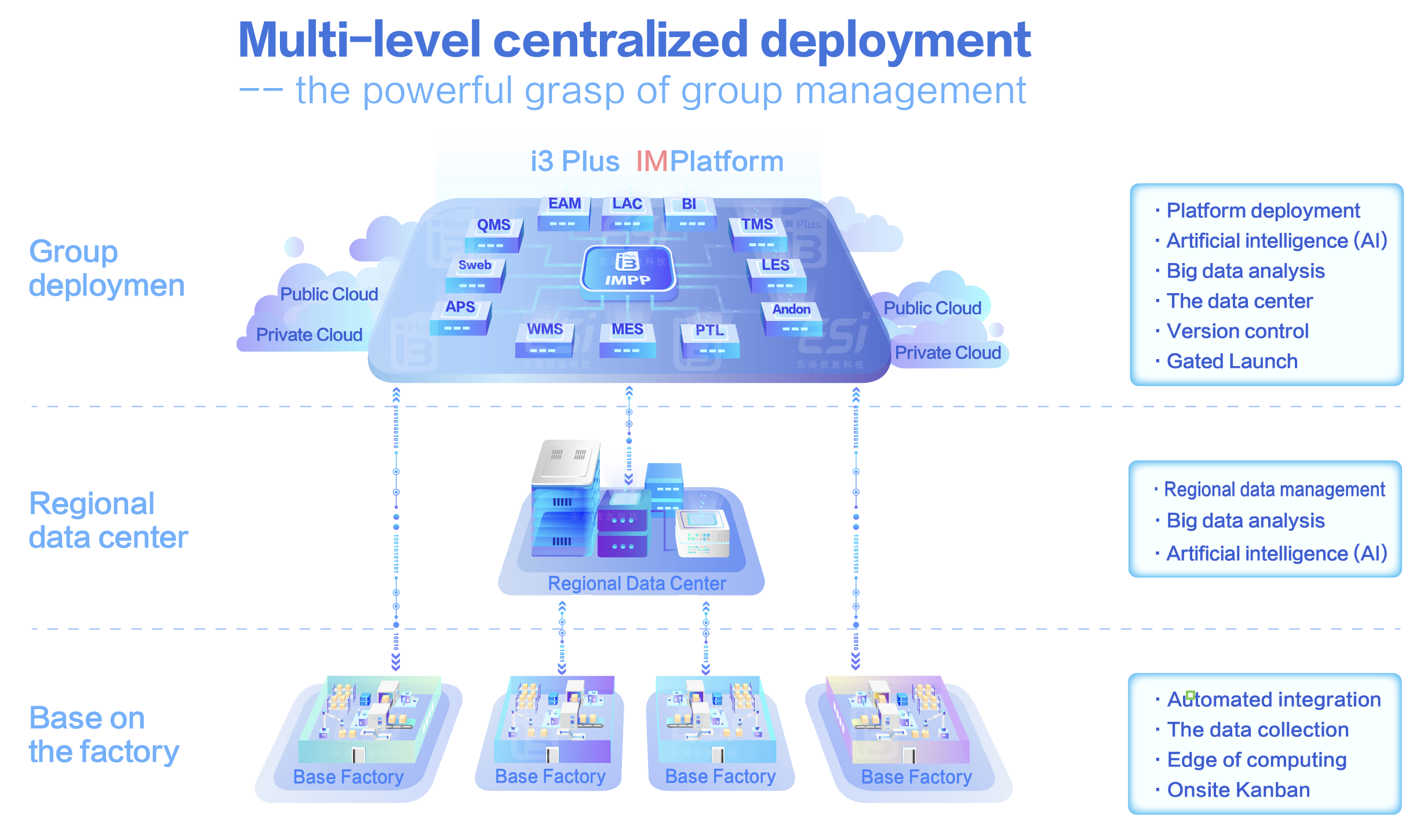

Based on Eastshine i3 Plus IMPP platform, MES system designed by MAGNA in Beijing includes: plan management, production management, quality management, equipment management, performance and analysis, system interface, Andon, eSOP and other functions. The Eastshine I3 Plus IMPP leverages its cross-platform universal service features to keep data acquisition smooth for these management systems.

· The most advanced international process configuration function

Make the process flow flexible and configurable, fully practice the process visualization in the system, configurable and highly flexible production.

· Material pulling as the core

The interaction of materials in different storage units should be taken into account to realize the logistics management of materials fromwarehousing, in-warehouse management, outbound, pulling, transfer to final assembly;

Realize pulling from warehouse to workshop;

Pulling from suppliers to factories;

Pulling types include kanban pulling, work order pulling, demand pulling, etc.

· Fine management of raw material inventory

Warehouse management of purchased parts, synchronous SAP purchase order information and mobile terminal scan and receive goods;

Manage the warehouse of self-made parts, produce and print Box labels according to daily package plan;

Case labels can be printed and bound to Box labels and pallet labels according to the material packaging protocol, so that the exact tracking of each piece can be realized.

· Multi-system integration

i3 Plus IMPP micro service platform;

i3 Plus MES products can provide full-scale managment to production line process, station work step, equipment interactive collection, ordering check, production process monitoring and production line monitoring, etc.

i3 plus WMS products can realize full coverage of warehouse material labels, fine logistics management, logistics distribution pulling, AGV handling and scheduling, matching account with reality, equal in and out principle, accurate traceability of materials;

i3 Plus Andon products combine MES products and on-site equipment to realize intelligent linkage of production process, timely call, task generation and task process tracking, etc;

At the same time, the quality management, equipment management, Sweb, eSOP and other multi-system integration, to achieve the factory intelligent management information construction foundation.

As one of the top three auto parts manufacturers in the world, MAGNA, together with this round of information construction, has greatly improved the level of information in the production workshop, improved the production efficiency, made the information management of the production line visible, and made the production information traceable. The successful implementation experience has been carried out in depth practice in several domestic plants and Thailand plants of MAGNA. The i3Plus micro-service platform, i3 MES, i3 WMS and other intelligent manufacturing management systems independently developed by Eastshine Information have won the trust of MAGNA with forward-looking product concept, diversified product modules, efficient implementation and high quality service.