Requirements:

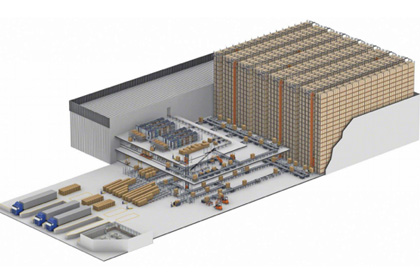

This system focuses on the management of finished materials. The system functions are as follows:

· Bar code management: bar code rules definition, basic information management and maintenance, product bar code generation and printing.

· Package storage management: post the barcode of the package and scan it through the automatic scanning equipment for confirmation, and conduct on-site scanning check to ensure that the products scanned online first are scanned offline first, so as to ensure the consistency of product production sequence.

· Outbound management: the system generates delivery instructions for outbound control. Warehouse administrator through the wireless data terminal at the scene of the warehouse for unloading, delivery guidance system can, prompt warehouse workers in material goods, for the material that need to be first in first out, the system according to the material batch number to check, for easy to inventory materials to dispatch first, at the same time, according to the shipping instructions for outbound material code and quantity check, Prevent material and delivery of wrong delivery, leakage and other situations.

· Shelf Validation management: on the premise of realizing bar-code management, Shelf Validation inventory no longer needs a large number of personnel on site to manually count and check statistics. Inventory personnel only need to use wireless data collector to scan and collect barcode labels of materials on site, so as to record inventory of materials. The system can not only check the system inventory immediately during inventory taking, but also prompt the material with inventory difference in real time. It can also make summary statistics according to the inventory scanning data, and automatically generate inventory difference report, which greatly improves the efficiency and accuracy of inventory taking.

· Report query: Based on the above service operations and data records, the system can provide rich service query and statistical reports, including the following query reports: production statistics daily report, production statistics report, time period statistics report, platform summary report, etc.

Technology and equipment used:

·Automatic scanning technology is used to realize automatic scanning through inductive scanning equipment connected with data acquisition equipment.

·PDA wireless scanning equipment is used to make the system more convenient to operate.

System benefits:

·Reduce the difficulty of product management in the warehouse.

·Scanning input instead of manual input, reduce mistakes, increase work efficiency.

·The introduction of barcode technology and mobile device scanning technology for unified inventory management.

·Inventory entry management solves the problem of product storage location and quantity, making inventory shelf validation taking easier.