Customer demand:

Sanlux Co.,Ltd., located in Shaoxing County, one of China's top ten economic counties, is a large enterprise specializing in the production of various rubber V belts. Since its inception in 1984, under the leadership of the chairman Mr. Wu, Always adhering to the "innovation for sustainable development, constantly leading the trend of the industry; taking quality as the fundamental, using quality to create value; Brand is the life; The company has achieved rapid development and become a national high-tech enterprise with an advanced enterprise of national quality and efficiency.

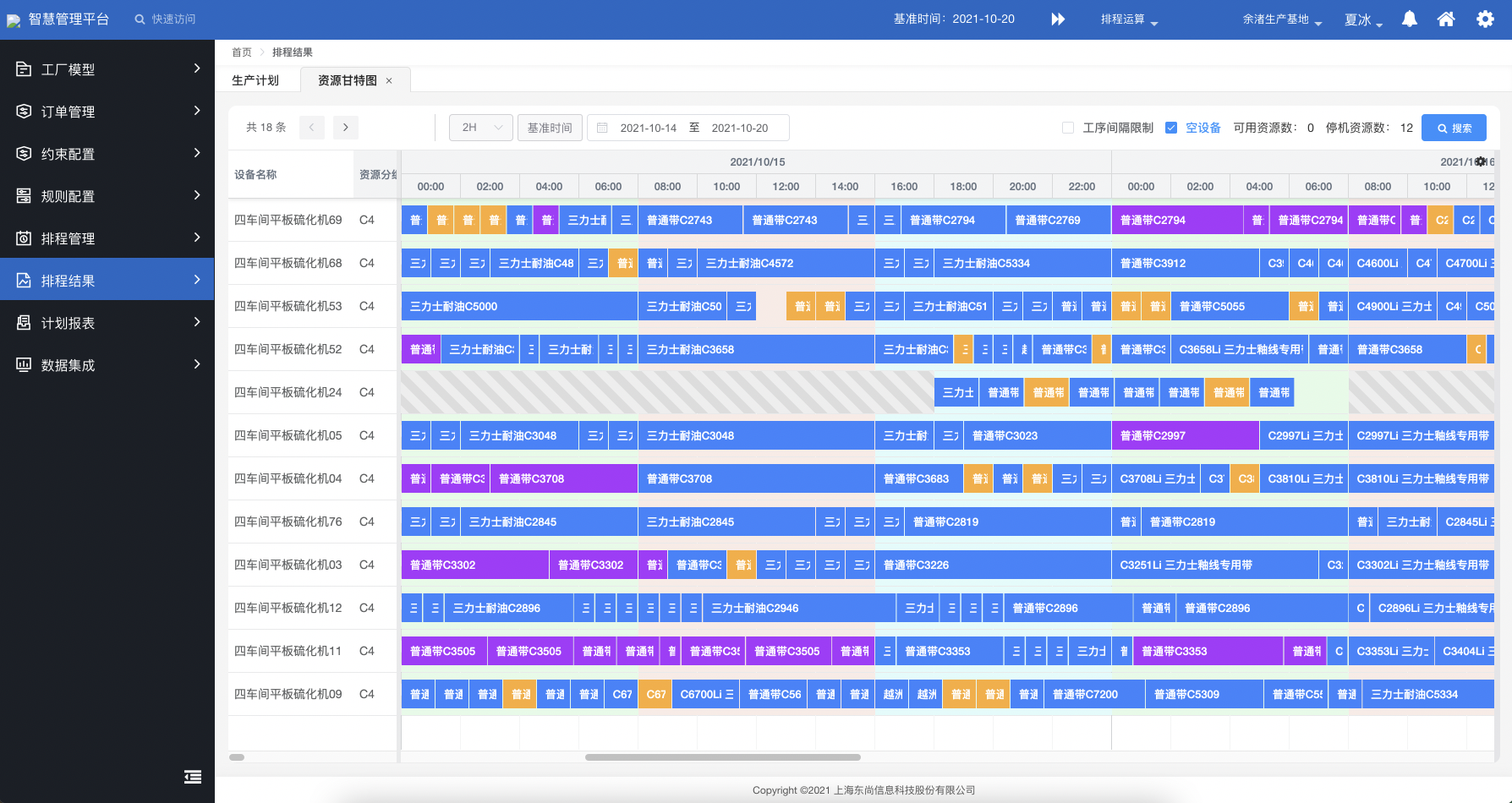

With the deepening of enterprise information construction and diversified requirements from product and market, enterprises introduce APS(Advanced Planning and Scheduling) system to comprehensively control the production management and material control process of enterprises. To solve amounts of customized products, Rich category, production planning is difficult , make full use of the advantages of I3Plus information platform, to achieve customized plan scheduling, dynamic real-time computing capacity calculation, simulation analysis and planning adjustment, self-defined rules fast response and adjust production capacity and production plan, promote the coordination between the production departments, eliminate information barriers between departments.

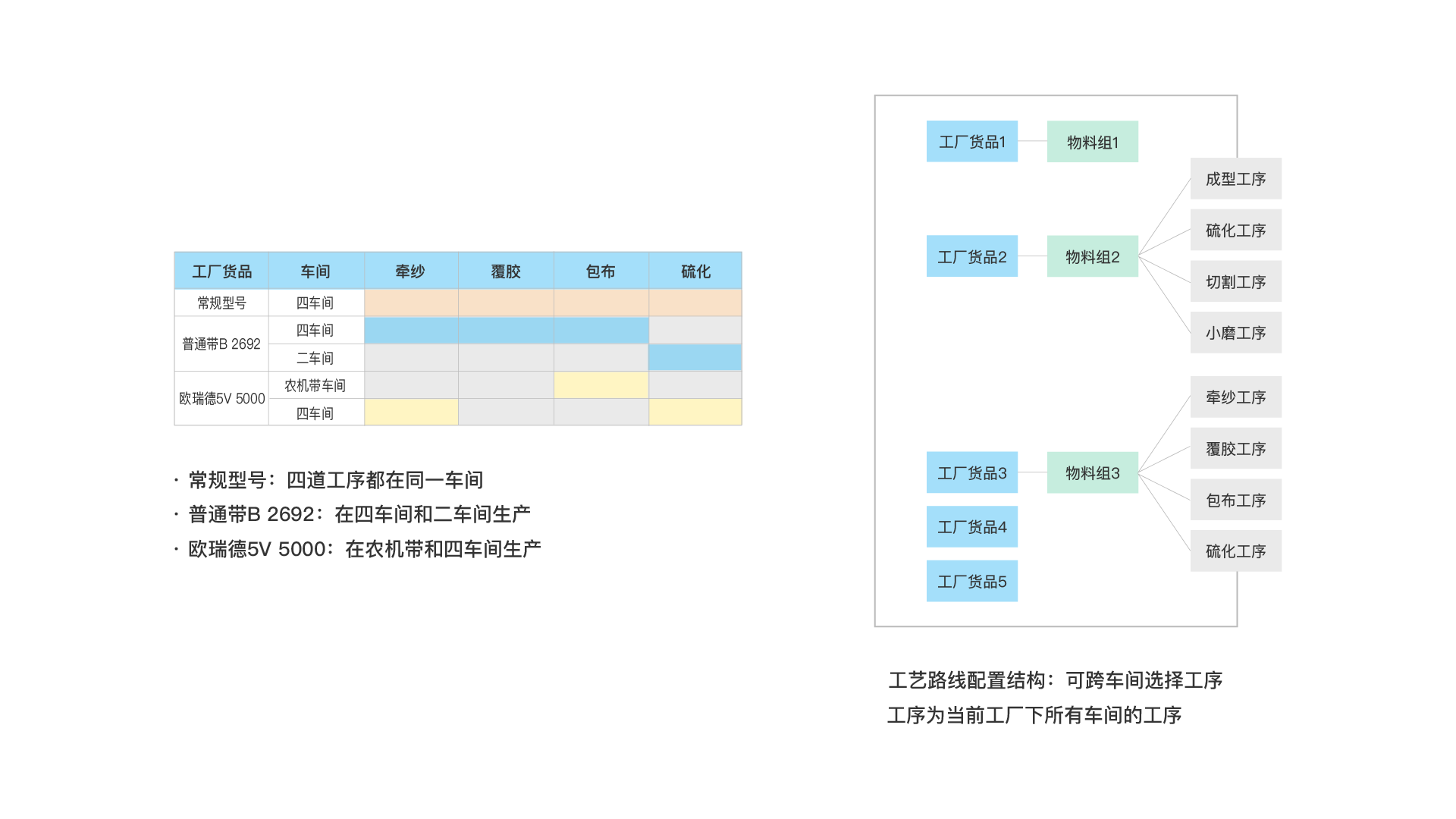

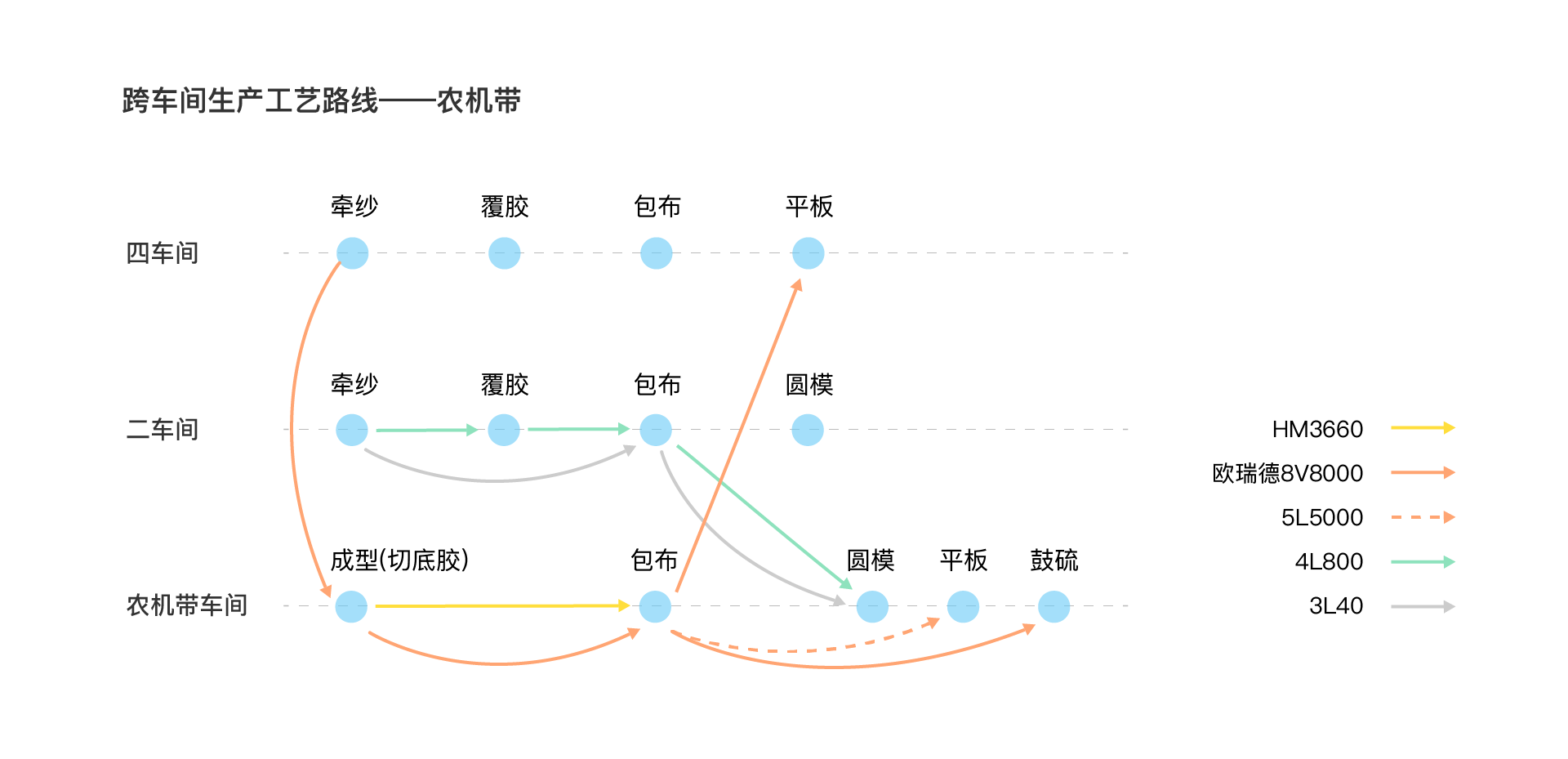

Process route: The process route in the material group can be configured with cross-shop procedures to achieve cross-shop equipment use for the specified factory goods.

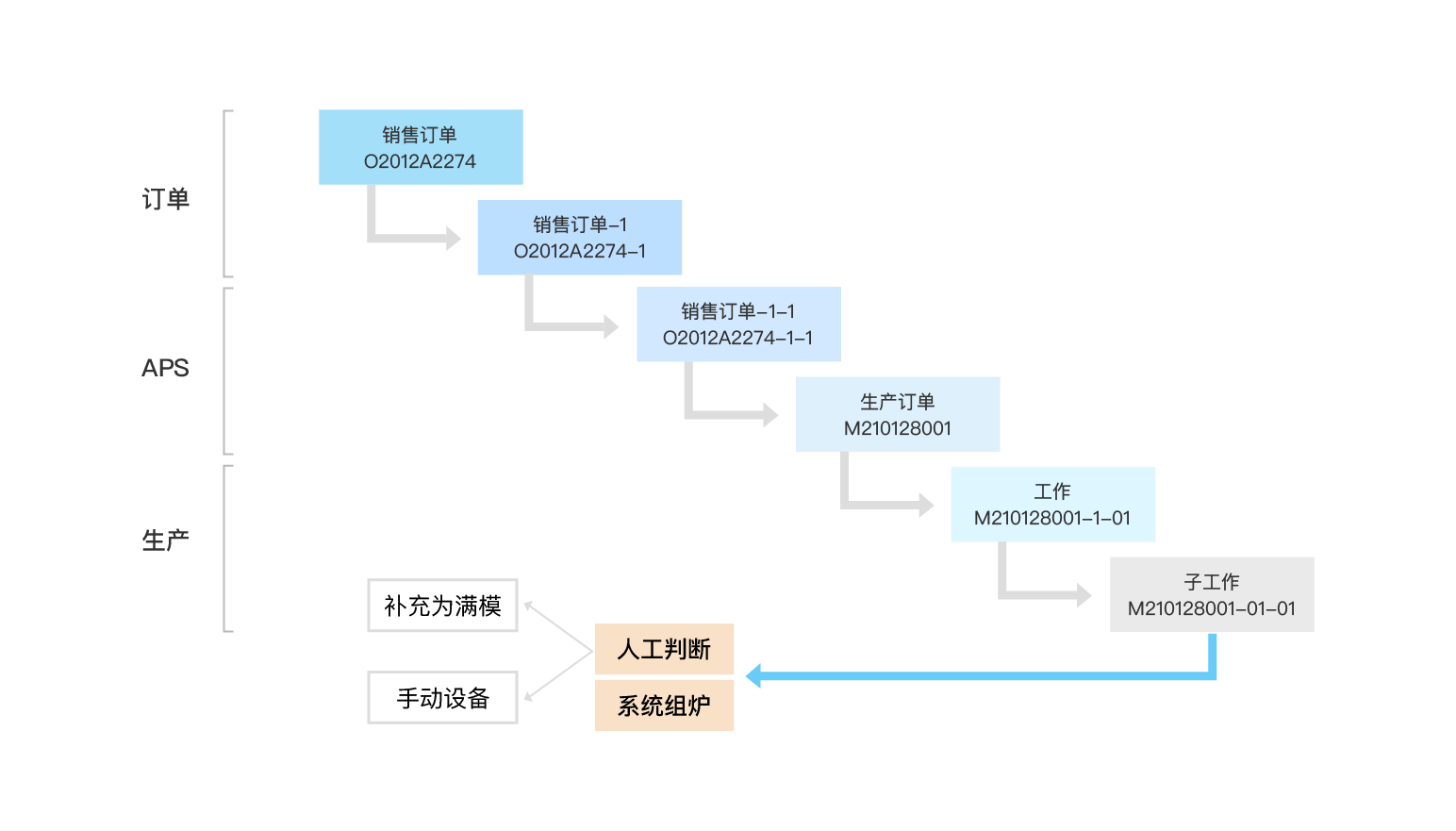

Order splitting process: after arranging the work of different processes to the equipment, the molecular dismantling work will be carried out according to the full module of different equipment, and the sub-work can be reassembled to improve the capacity.

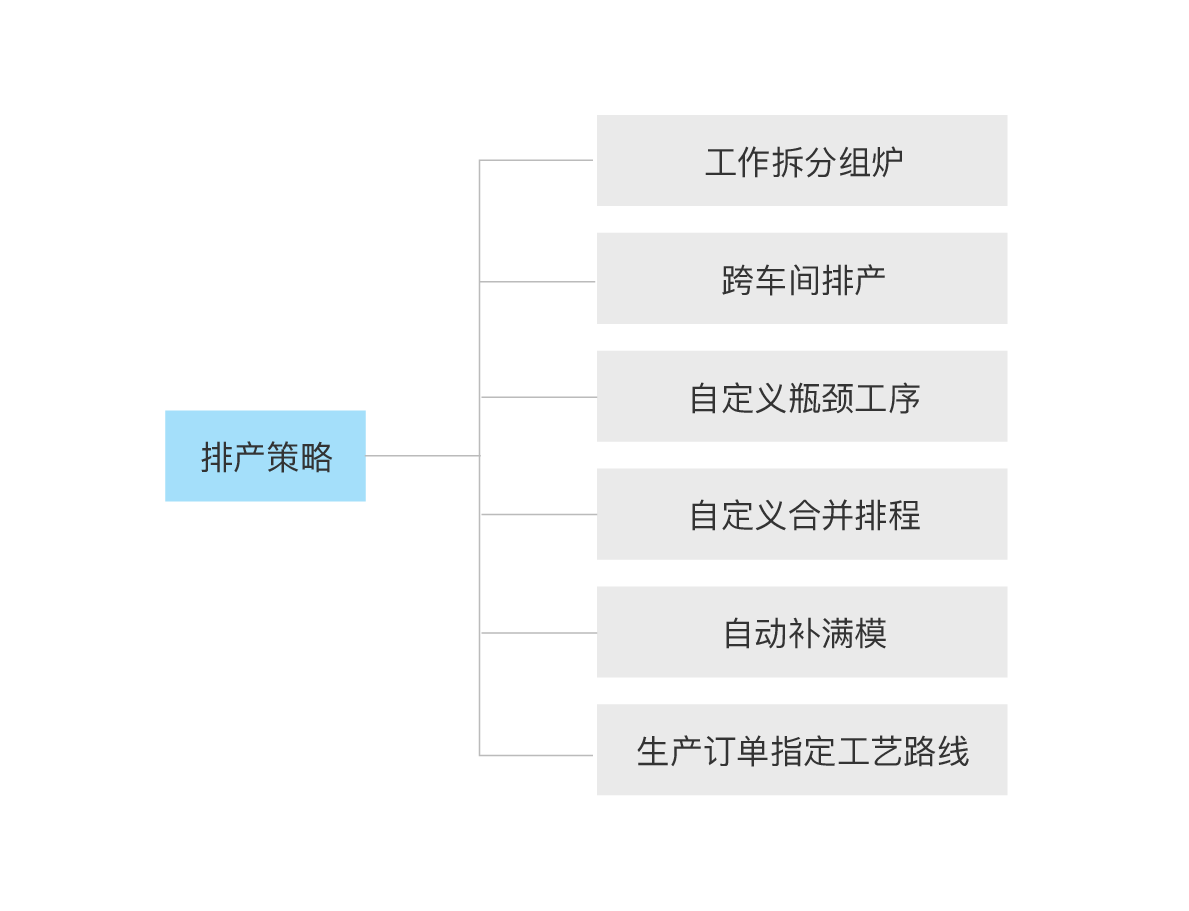

Production scheduling strategy: after the work of different processes is arranged on the equipment, the full module will be dismantled according to the different equipment, and the sub-work can be reassembled to improve the capacity.